You can do this using DMT no problems.

Kind of irrelevant as far as actual Epicor features go, but I’d really be interested into more training than just the ICE Tools and Customization user guides.

I’m not exactly from a programming background, but I have done a small amount of Vb for an internally developed application. We have not completed our implementation, but as far as customizations go it seems like the sky is the limit, and I’m not sure where to start.

SSRS execution log view will give you the runs of that report. By default SSRS keeps this for the past 60 days.

USE ReportServer

GO

select

ReportPath,

UserName,

TimeStart,

TimeEnd,

Status,

Format,

Parameters,

TimeDataRetrieval,

TimeProcessing,

TimeRendering,

(ByteCount/1024)as KB_Size,

AdditionalInfo

FROM ExecutionLog2

ORDER by TimeStart DESC

Epicor Telemetry? ![]()

Not everyone has DMT, it’s not a standard package.

With regards to DMT. It should be standard AND there should be a library of standard extractions for common platforms…Basically a business within itself. So sorry if I’m standing on anyone’s toes here, but thinking of ways which make it easier to adopt a new ERP.

***Added to the Features and Requests

On the where used screen you can check out multiple parts at once.

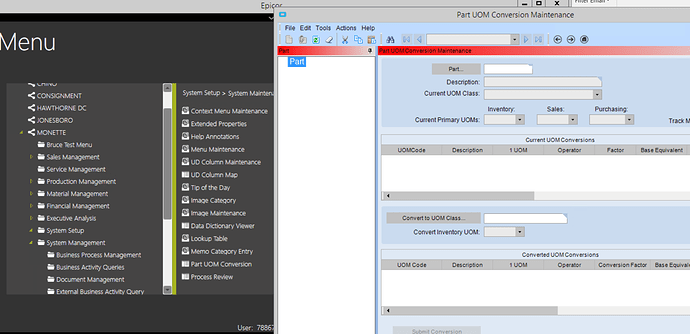

Make it possible to change the UOM Class and UOM on parts that have some transactions.

Change parts to have a Partnum in the background like custNum and VendNum to allow fixing part’s that have some issues.

Total selfish one here. It would be great to be able to delete the whole PO from the Container Landed Cost instead of line at a time. You have the ability to add multiple PO lines, but not delete, which is a shame.

Going the customisation route for the time being.

***Added to Feature Requests and Suggestions

I have actually created an updatable dashboard for that… I have also submitted this to Development so that it can become base. The updatable dashboard allows you to “Add” a line… it asks for the part number, and then looks up the “current” revision… then it asks for the new revision (if you want one), then the ECO Group. It auto creates the revision, checks out the new rev, and gets details… then goes to a new line for the next part. Since its a dashboard, it allows for copy/paste into the dashboard. built 100% with widgets (if I remember correctly). Sorry to say, each time I have built this, it has been custom because each customer has needed UD Fields in PartRev also filled out.

This one is tough… part revisions require an entirely new layer of data, with new indexes. The best workarounds include:

- using LOT CONTROL to specify the revision.

- using a part suffix to store the lot number (used a lot in Aerospace)

The way I describe our part/rev system is that all future revisions should be design enhancements of the old rev, and should be backwards compatible… but if the new design is not backwards compatible, then it needs a new part number. At my old employer, we took this approach WAY back before computers (1950s) and used Lot numbers to control/track what part revision was actually delivered… they still do this today.

gee tks never thought of using DMT for that!

But I agree with Randy and Simon as Not all have DMT and IT Should be part of the standard package not an option…

Nevertheless, needing to go DMT for this I think would be a more lengthly process than just offer it within the Maintenance form…tks for the suggestion though…

Pierre

But only for parts that the part you are looking at goes into. If you just have list of parts you can’t (unless I’m missing something…)

Provide BAQs to Trackers that can be amended or linked to other tables. Currently, this can be accomplished using a customization and a BAQ dv. However, it would be so much more useful to provide a system BAQ that can be automatically enhanced to link to other tables.

Each form has Global Options - but they are not global. Let’s let the user set these things globally and not have to do it on each form.

Territory Security - the current implementation makes it impossible for a salesperson to work on an entire account (parent in one territory, offices in another territory) when you have one Salesrep per territory and are trying to protect your overall account base from being stolen when one disgruntled salesrep leaves - for example that is.

Plus it has other limitations when working with international customers, or working with BAQs and Dashboards for summary information, pipeline reporting, etc.

Enterprise Configurator - be able to ‘Get Details’ in the Sales company, from the manufacturing company, so Cost+ calculations can be made.

Currently, the only way for a sales company to be cost+ is to build a replica of the entire MOM/BOM inside the configurator code to calculate the same thing “Get Details” does.

Added the option to “UpVote” on this question to bubble the most popular suggestions up.