I come from an Technical/IT background but have been tasked with redesigning our Inventory Process. Can anyone provide direction and or material on how Epicor is designed to work with a process.

This is a HUGE topic… Just the word “Inventory” can mean so many things… Are you referring to how you STORE inventory? How you track it? How you count it? Warehouse/Bin arrangement? Pick/Pack/Ship process? Multi-site inventory transfers?

Just trying to narrow down the focus.

Wow. Are you sure you don’t want to do something easy first, like building a fusion reactor out of spare server parts?

I feel your pain, back in the good old days I was an IT guy and got the same marching orders. Has your company ever taken a full physical inventory, and have you ever participated? Did the company try, fail badly, and that’s why it’s now on your plate?

hahah… My first few programming projects during my first year at my new job back in 1983 at a manufacturing plant:

- Create a Production tracking system

- Create a Sales Backlog tracking system

- Then… “Hey Tim, can you write a new Inventory tracking system? It needs to also handle lot tracking, and our old system doesnt do that”

- THEN… “Hey Tim, can you write a cycle counting system?”

As a new programmer, it was the absolute BEST way to learn business! within a year, I learned so much that I had never learned before. I had business mentors that didn’t know programming but DID know business. They explained what “Backlog” is, and proper controls on inventory. Mistakes were made, but wow, i learned a ton. @shoebasset, you can take this opportunity and run with a super rich toolset that Epicor provides! You have some learning, but the GOOD news, you don’t have to write it all from scratch like I did.

That would have been amazing. I’m not a programmer (just ask Jose!), I had just been hired as the “Epicor guy” in a company that had badly failed every semi-annual full physical inventories in memory (variances of over 25% of total value), and were using a home-grown process that almost actively discouraged accuracy. It took two years, but we got the variances down to less than 3% by using the out-of-the-box Epicor functionality.

The things that fixed it? Transaction discipline and continual training (well, and a CFO that cared).

Having pizza and some contests on count day also helped.

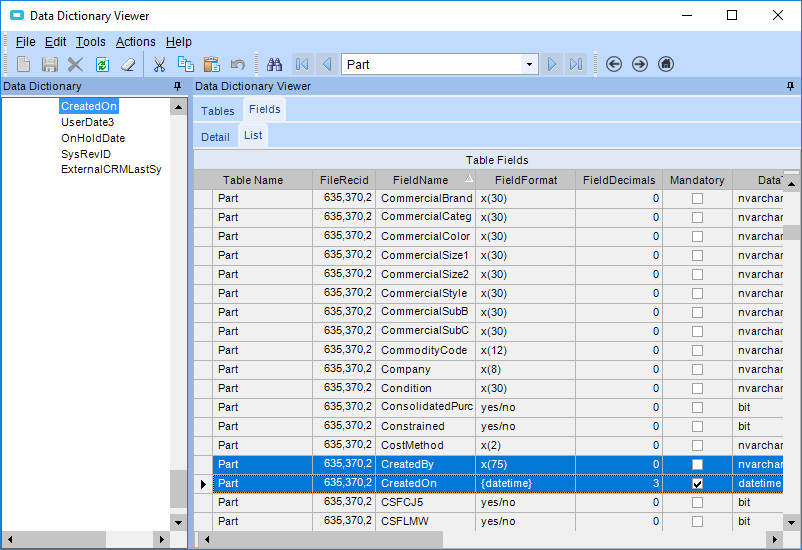

I personally would add a UD field for CreateDate. Also add a BPM to populate that field on GetNew.

Finally!!

And not just Part, quite a few tables I’ve checked.

Out of all of the beasts involved in the Inventory topic - the implementation of physical inventory in E10 is my least favorite. So much so that at my last company I wrote a whole implementation from the ground up.