Alright, I’m needing to do a waste percentage based on the material that comes into the place and the amount being sent out in sales. I know there are variable to consider, but the big one is we do not want to use the Scrap field as a way to measure waste percentage. Higher ups doesn’t want to leave that up to human decisions on the floor. I have started one but everyone says the numbers are off. So, wanted to reach out and see what others thought about how to build this one and i could see what tables, etc. Then possibly be in a good position to change mine. Or the issue could just be in the way they are doing things. But that’s another matter entirely.

Write a query that adds up your Purchase transactions and compare that to outgoing transactions and on hand balance (assuming that’s accurate). The difference is your scrap. All of that is in the part tran table.

For those that say the numbers are off, ask them where they got their numbers… (we have the same problems with believing data)

Thanks! I’ll pull that and see if there is any difference. And yes, that is a valid question I am looking into now. Thankfully the company I’m with gives me the latitude to investigate the process and see how it all lines up in various ways. So in this case I am combing through hand written data and asking questions on their processes to understand where the issue is.

Well for me, Part tran has NOTHING in it. LOL! So, Unless there is another option I’m gonna have to stick with jobhead,jobmtl and Part. Truthfully we are dramatically under utilizing Epicor. So I have found numerous places info should be but isn’t. Don’t fully know why but the more I dig the more I learn!

We bizarrely used to manufacture a stock item that could physically sit in the warehouse as a finished item for weeks or months on end before the part was consumed in a full assy. In someones wisdom it was decided that the several materials used to manufacture this particular stock item were to be consumed in the full assembly as a phantom BOM. We manufactured 100’s of tonnes per year of this item running the plant on 3 shifts x 5 days a week.

The materials and finance guys were forever carrying out stock adjustments worth $000,000’s due to inconsistent stock counts.

I’d argued for years that using a phantom BOM this way wasn’t suitable for this particular item but it continually fell upon deaf ears. The business hierarchy had a vision that the stock item was only a physical item for a number of hours before being consumed and didn’t warrant having to create a job to manufacture it in the first place, whereas in reality it could sit as a finished item for weeks, months or forever without ever getting consumed.

How’s this related to the OP query?

Well, scrap factors can be important because BOM’s are only theoretical recipes at the end of the day and in the above example the top level phantom BOM only accounted for a scrap % of the stock item going into the finished assembly. It didn’t allow for the scrap % that was used during the manufacture of the part itself. Therefore it was almost impossible to track what the scrap % of each material that made up the stock item was. This was were the guessing came in from those that knew better and what led to massive variances.

I eventually convinced the business to trial Kanban receipts to manufacture the stock item. We made a few batches based on the theoretical recipe and ingredients then measured what was consumed versus what was weighed as a finished part. This gave us the baseline for our scrap allowance for the stock item.

We also now have a second scrap allowance that’s based on the theoretical weight of what we think the finished assembly consumes of the stock item versus what we physically have left over.

Stock levels over the last 12 months or so since I implemented this have never been more accurate, (albeit, it never had to improve much to become more accurate

So, to conclude. Scrap % can be useful if it’s used correctly but I wouldn’t bother with them unless they were part of a long running job that can be measured and amended. I wouldn’t wish anyone to experience what we went through due to sheer stubbornness of certain managers.

Cheers,

If PartTran table is empty, then you must not use PO’s, or receive any materials, or issue any materials? Are you even able to have a live inventory? Without those things being done, how would you be able to keep track of anything?

@Matrix1 I can understand! Fortunately for me, management is giving me a lot of room to make this work from here on out. I think I figured out the issue though. In the past every dept manager would keep track of waste manually. One dept manager was using the operator’s data, or taking the workers word on what he did. And that was throwing his numbers off. WAY off. So, this is just another hurdle in making this work better while having to retrain people how to log things correctly. But thanks for the info!

@Banderson That’s a good question! But for the most part, there are no numbers nothing. And I brought up the Entry person in this table and the person who entered it was only one person and that was my predecessor. So I am thinking they are using it in a different way than is optimal. Definitely something for me to look at and see what they are doing. I know we do inventory every month, we take and use PO’s, receive materials, and issue materials. But apparently they are not using the parttrans table for that. And that is interesting to me.

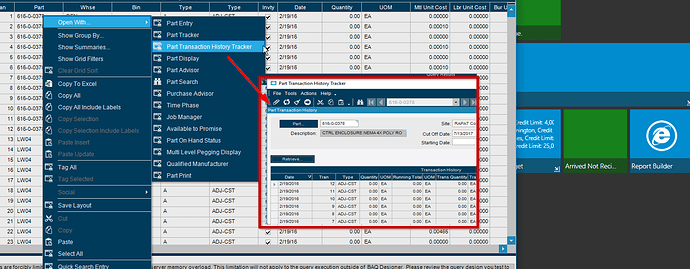

I don’t think you understand when I meant to look the PartTran table. That’s the database table that records all of that stuff for that. It cannot be empty. Also it’s not something that gets entered by hand. All of the things that happen that have to do with inventory is writing to that table. It’s not a function of if someone does it or not, it’s a core process that makes Epicor work. If you go to a part that you you and right click, open with, part transaction history, that’s the table it’s looking at.

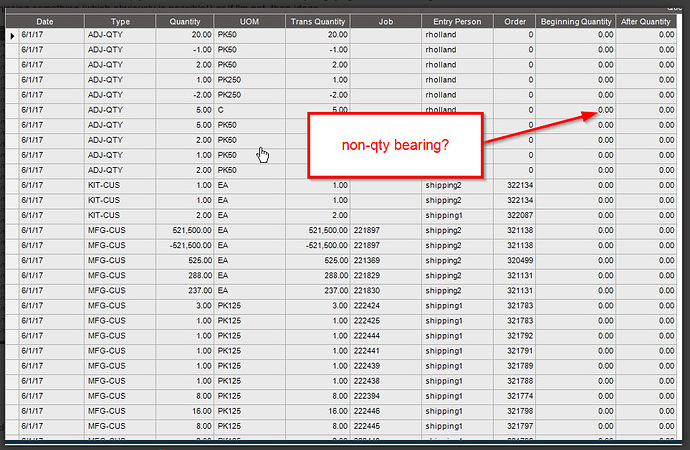

is the PART quantity bearing?

it doesn;t make sense that no PARTRAN records exist

If you are BUYING materials - STOCKING them - and SHIPPING them

and then finding out that you BOUGHT 1,000 EA in 2016 … and SOLD 800 EA in 2016

and have NO INVENTORY balance remaining AND

NO INVENTORY Adjustments, then you dont have a scrap problem, you have a pilferage problem …

unless in the ACT of taking product off the shelf and shipping it - there is loss

such as spillage, spoilage, shrinkage, shelf life … IDK

it doesnt sound right

Didn’t think of that. That would make sense. If they do a physical every month, that would mean they don’t have live inventory (otherwise why would you count it each month). But all inventory non-quantity bearing? That’s interesting…

Ok, So, its not COMPLETELY empty. But seems useless for waste. Can you guys give me some insight as to if I’m missing something (which obviously is possible!) or If I’m not, then ideas…

So if you sort our your pur-xxx transactions (that’s what’s coming in) to your going out transactions xxx-cus or stk-mfg or whatever, you’ll have to look through the list. Then you have in’s and out’s and there will be a difference. That really should add up to what your adj-qty transactions are. So when you adjust your inventory you are basically accounting for scrap. If you have enough time and data in to smooth out the highs and lows you can get a running average of what your scrap rate is. You can do a query with a subQ of the “in” transactions summed and grouped by part number, and your “out” transactions summed and grouped by part number, then subtract the two, divide by your usage (outs) and you have a working scrap rate, based on history.

The hardest part about this is to be able to account for outliers and wierd things that throw stuff off. Not usually a big deal, but you should look through the part tran of anything that seems unusually high or low.

Do you know how to make a query like I am describing? or is this just greek to you? Everyone is at different levels around here about how much they know and can do and I don’t want to assume too much.

Also can you check in your part entry/tracker and see if the quantity bearing is set to true? The fact that the quantities aren’t changing is interesting.

I understand what you are saying. I do find this interesting and worth an in depth look. I checked a few parts quickly and saw they are Qty bearing. But 'm going to run a query and see for every part. I’ll be back with pics and questions… LOL! Thanks for the patience and info.