We have done full, physical inventories in the past and want to move to Epicor’s cycle counting to replace those starting next year. We average about 2700 SKUs in our inventory at any one time so our thinking is if we count 50-60 parts per week, one day each week, we should have almost a full inventory at the end of the year. I’ve set up ABC codes (30/60/90 days) and assigned them to our parts. I am having a struggle defining cycle periods.

If I set my cycle period for a month and set 12 periods for the entire year when it calculates the parts to count it gives me something like 500 parts per day to count. If I set 1 period for the entire year and use a production calendar with 1 day to count I get about 56 parts to count. This seems closer to reality but leaves us with a bunch of questions.

During the part selection no parts were chosen more than once, even A code parts that should be count every 30 days.

We are an engineered to order company and can have new parts enter the system, be made, go into stock and be used or shipped within a month. How is that handle by cycle counting when selecting parts.

Speaking of which when do we select parts for cycle counting? In my test I selected all parts for all periods (52 weeks). Do we select parts just before counting?

How is everyone setting up their cycle counts. While there’s some good information in the Epicor hands on course it tells you how to do a lot but not really why you should do it.

Loaded question Rick! Lot of things to digest there.

I would need some time to think about it, but I’ll review what I set up many moons ago and see if I can’t answer some of those things.

I’ll try to break it into smaller chunks. How many cycle periods do you use? How many parts do you count each period. Maybe we can start from there and grow.

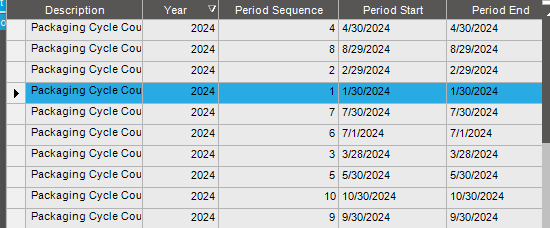

We cycle count our packaging because nobody issues it right now.

We assign that “P” ABC code to all the parts we want to count:

Then we do a count every month.

So it looks like you have 12 cycle periods (monthly) that lasts 1 day each. Am I reading that right? Do you count every part each month or just a sampling?

What is your “P” code used for? It looks like you count it every day?

I think we do have some items set for daily…not many and all in a specific area of the warehouse. We did on our old system as well…

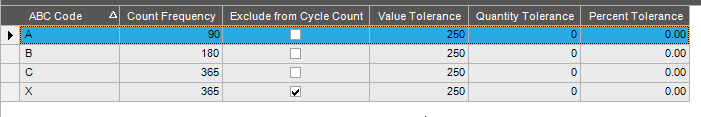

That’s going to depend on many factors. We have three levels of items we want counted and a fourth we don’t want cycle counted. Our ABC’s are setup thus:

For our warehouse, we have counts going on daily of about 50 parts to spread the load and not have to devote someone to just doing counting.

How many cycle periods do you have? At the end of the year have you counted almost all of your SKUs?

I guess I’m trying to break it down to a few things we’re looking to do.

- Cycle count a few parts weekly that would cover our inventory at the end of the year to replace a full inventory.

- Be able to count the items that need counting more often “A” codes.

I have more but if I can get us there thats a great start.

At the end of the year we will of counted every SKU in the A B or C codes at least once or up to four times depending on the Count Frequency.

Let’s start with the math… how many part numbers do you have that are “A” parts? How many are “B”, and how many are “C”? Multiple the “A” total by 4, the “B” total by 2, add those results to the number of “C” parts and THAT is how many “part numbers” you will need to count over the course of a year.

In practice it will be fewer than that, since you can exclude zero QOH parts (and some others), but if you take the total from above and divide by the number of days in the year you count then you have a rough idea of how many parts per day Epicor thinks you need to count.

Yeah, we have a few non-nettable parts that are A, B, or C as well as zero QOH. Our system works for us but your formula could help @rturrentine.

These ideas are in conflict.

You’ll have a full inventory every 90 days if your longest code is 90 days.

If you want to count C parts only once every 360 days, C should be 360.

So we have about 58,000 part numbers total, of which, we only have about 2700 on average in inventory at any one time. I have 6600 A code, 12,000 B and 38,000 C code with about 10,000 not counted part numbers.

If I tell Epicor not to include zero quantity parts then it should come up with the 2700 number too, correct?

This makes sense since I do only want to count my C code parts once per year. Maybe I should stretch the B code out to 90. We probably only want to count them 4 times a year.

I will make these change in the Test system and see what it yields.

To do a proper setup and test, you need to:

- Null out the

PartWhse.LastCCDateon all parts - Run the Initialize Last Cycle Count Date process

- Do all that other setup (ABCs, periods)

- Then test