We have an issue in our UOM. We have been using SH as a UOM with No Rounding and 4 decimals. This is giving us, for instance, a Qty/Parent of 0.3333, and a Required Qty of 0.3333.

However, we usually take these sheets, use pieces and toss the offal, so basically using a full sheet.

It was brought up that we just round off the UOM of SH with no decimals since we use the full sheet usually with the offal being tossed, so 0.3333 SH becomes 1 SH, 1.25 SH becomes 2 sheets, etc.

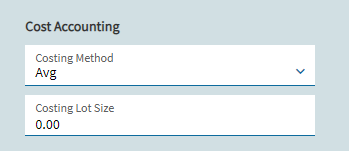

We had done a test previously where we changed this on our non-production server and everything seemed to come through okay, finance signed off, but somehow, now we are seeing big jumps in costs, as the inventory is being seen as the rounded up numbers.

Is there a way for the cost roll to use the qty/parent in the BOM for costing instead of the rounded up required qty?