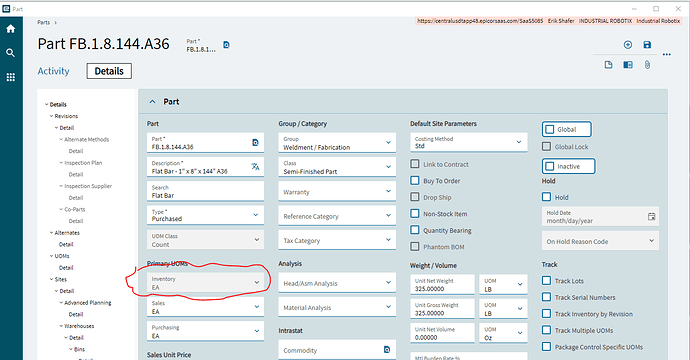

Some of my mfg and purchased parts allow me to select different UOM we have set up (like ft, in, ea, etc)… for some reason some only allow me to use EA, and the “inventory” UOM is grayed out… I cannot seem to find out what is different between these and the other parts. Probably something stupid, but does anyone have any ideas?

That’s really odd because I literally just created these. So could it be a bug?

We had to stop the entry person from setting an initial standard cost because that would make a parttran cost adjustment record and the part could not be changed or deleted.

If you try to delete the locked part does it give you a warning?

Yes. Found that it wasn’t as new as I thought. It’s on a BOM.

But that begs to question - how do I change the UOM now?

Remove any parts on hand, then you should be able to edit the part. Make sure to add your parts on hand back in. I think you can use Quantity Adjust for this.

I am not certain, but you may also need to close any jobs that reference part transactions.

EDIT: I defer to smarter people!

You can’t by the rules change the UOM if there are parttran records, if there are on hand removing them will not allow a change.

the official answer is to inactivate that part and make a new part number.

If it is ONLY on a bom update the bom and then see what messages show.

this is very disappointing.

thank you everyone for the quick help.

I feel that might not be 100% correct. I was under the impression that:

- The UOM Class was what really causes the issues with the UOM change process.

- Changing the IUM (but staying in the same Class), could be done with lots of preparations: No QOH and No open demand (Mtl on Jobs, Jobs to make it, PO’s, or SO’s, etc…).

- Presence on BOM’s could be problematic - the Qty Per and Units don’t change to reflect the new IUM. Like if the current IUM is FT, and a BOM calls for “0.5 FT”, changing the IUM from feet to inches, via UOM maintenance, doesn’t update the BOM to “6.0 IN” So a user might be expecting the QTY and UOM to be in the new UOM, but only changes the Qty as need for the specific job.

But then again the UOM system seems to be more exception, than rule.

EDIT

I must say that my last experience with Epicor was with 10.2.300. So take what I say as possibly outdated

I would not say to give up yet. If is in on a bom and sales order it is not too hard. Are there transactions? If so how many?

I believe it is an issue with capture integrity. If you have unposted transactions and costs in one base IUM you could potentially open a can of worms by allowing a change at that point.

They provide data fixes so it is possible to update, just not simple.