We are an electronics company and some components need to be tested by United Laboratories(UL). Is there a field that can be checked so reports and audits can be generated?

I don’t think there is one out of the box, but you can add a field in UD Column Maintenance, and regenerate the Data Model.

Then you can add it to your form.

I could’ve sworn someone asked this a short while ago… and it was you…

Day drinking has it’s downsides.

But if you drink enough, you won’t care.

We have part features we wanted to use for grouping, sorting or searching. Instead of adding a UD field, we used the Attributes section in Part Maintenance. Some fields available would never be used in our business so I changed the field’s label and we enter the information in those fields. Maybe not the best way but it was an easy fix that worked.

Easy yes… but hijacking fields isn’t recommended.

I’ll admit I have done that in the past, but later it had teeth.

I just add the column now.

I have UL and a few others that are on a part that I copy to the order. In addition to the requirement I also have a checkbox for completed. In shipment entry if required is check and completed it not check they get a message on opening the pack telling them that the order will not ship without the paperwork completed checkbox set and tells them who the responsible party is. I then do not allow the pack to be closed which prevents freighting and shipping.

Wow… thorough implementation!

When I was trying to solve a similar problem ? years ago Dynamic Attributes seemed like an elegant solution, but at the time you could not DMT that data so I took a different direction. I believe they have since remedied that so you may want to consider it.

Took a couple of customer corrective actions to get it started, but now when a new one comes up quality just asks for me to clone the process.

yeah, I was wondering if this thorough build was audit driven, haha.

I agree that is not a good practice but sometimes I am required to go outside of the normal process to satisfy the immediate need as stated by management. It can be very frustrating. I didn’t change anything about the field other than the label. We use the ThicknessMax field to represent our products working pressure. If there is an inherent issue I should consider I would appreciate any feedback.

If you’re never gonna use it, and it’s not used in any calculations or validations that are built in to Epicor, the risk is minimal.

And I say again, we have done it. (You are not alone.)

But… It is only marginally more work to do it the right way, and add a field. ![]()

I think instances like that are probably safe… there are old fields on some tables that even Epicor has stopped using. In those cases I get real nervous because you never know when THEY might decide to trash them and/or repurpose them and then your work may be compromised.

Exactly the ones I was thinking of… very recent example.

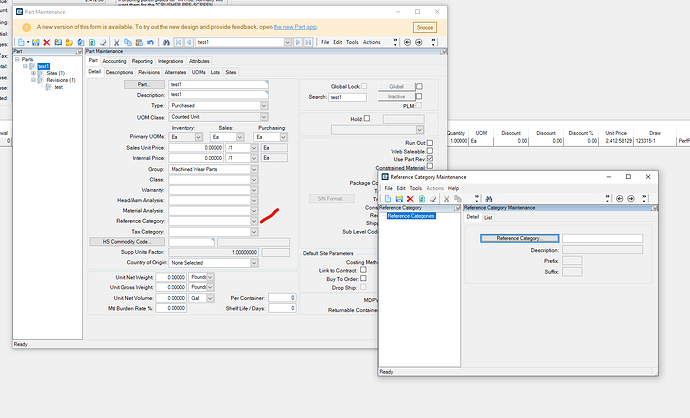

If you are going to hijack something, maybe reference category? A category of “UL Inspected Parts” ?

It’s actually Underwriters Laboratories… my dad worked there for 40 years or so. I’ve added UD fields and/or Supplier Attributes for years.