Have you tried Epicor support? I know they used to have answerbooks on some of the RDD based reports but not sure they still maintain those.

In the meantime, here are some (really) old notes I had on shop load report,

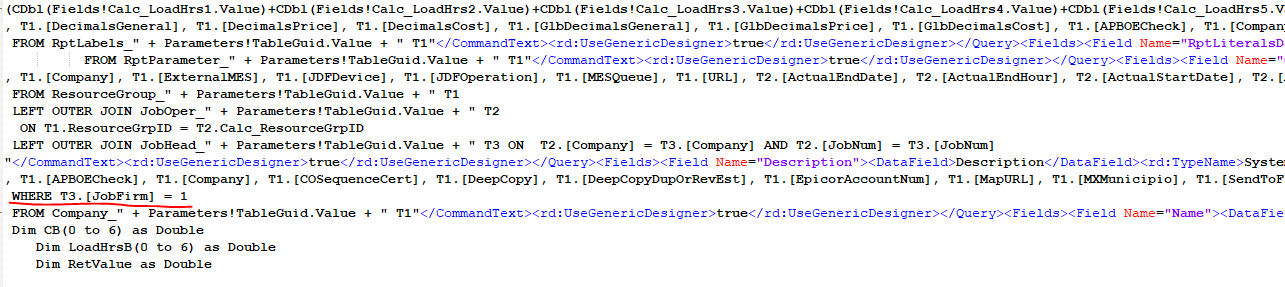

Table references:

JobOper (Operation information for Jobs).

JobOpdtl (Defines the Resource Groups/Resources/and or Capabilities required for the JobOper).

ShopLoad (Summarizes resource group load hours by day).

LaborDtl (Manufacturing labor transactions that reduce the load calculations, a subset to the LaborHed file).

ShopCap (records exist when ResourceGroup capacity is different from defined ResourceGroup.Capacity).

ResourceGroup (was WorkCenter in versions V6.10 and prior)

Resource (production Resources)

ResourceTimeUsed (time that a resource is scheduled, allocated to a JobOpMac).

ResourceTimeUsedSub (child to ResourceTimeUsed used to track concurrent capacity of a resource).

ResourceCal (Calendar “exceptions” for a specific Resource, which is using a ResourceGroup calendar).

ProdCal (valid days for production).

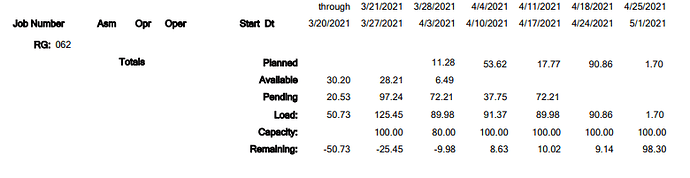

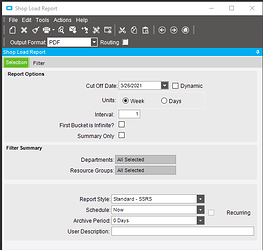

Calculate the time periods for 7 columns : per Cutoff Date, Unit and Interval and “First bucket is infinite?”.

Each column has a Begin Date and End Date.

1st column Begin Date = Cutoff Date - the time interval selected. (No Cutoff Date if “infinite” option is chosen)

1st column End Date = Cutoff Date.

Subsequent column Begin Date is equal to the End Date of the previous column plus 1 day;

Subsequent columns End Date = cutoff date plus the time interval.

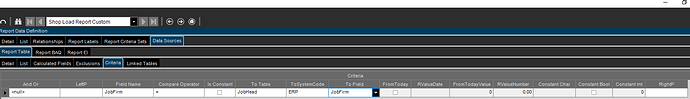

Read the Resource Group file by Dept/Resource Group for the Resource Group selected.

Read each JobOper record for the Resource Group

Skip closed jobs and completed operations

Skip if the scheduled Start Date is greater than the end date of the last column

Skip if there are no setup and no production load hours

Sort selected operations by Start Date and Start Hour.

Calculate Capacity : For each new resource group, the capacity is calculated for each time slot according to the number of production days that fall between the Begin Date and End Date, (based on the production calendar), times the Hours per Machine, times the Number of Machines for that resource group.

Capacity = Days * Hrs/Day/Machine * # of Machines

Example: The capacity for a resource group with 3 machines that each work 10 hours per day in 7 days, where Saturday and Sunday are not on the production calendar is 5 * 10 * 3, or 150 hours.

If the first bucket begins date is earlier than the current date, use only the production days from today forward for calculating capacity. Capacity does not exist for days already passed.

Calculate Load: Spread the load hours for each operation into the appropriate time slots, by working backward from the operation Due Date/Due Hour a day at a time, until all load hours have been applied. Production hours are applied first, then setup hours (moving backwards in time, this fits with the logical progression of the job. The assumption is that setup must be done before production.

The calculations for the load hours depend on the Load Relieved By setting in the Job Management module configuration.

- If relieving load by quantity:

Production Load = Estimated Hours per Piece * Qty Remaining

Production load equals zero if the quantity completed to date exceeds the original planned quantity.

- If relieving load by hours:

Production load = Estimated Production Hours - Actual Hours to-date

Production load equals zero if the hours to date exceeds the original estimate.

- If the operation is marked as Production Complete, the load hours are always zero.

- If the operation is scheduled to run on more than one machine, the load is divided by the number of machines.

- If the operation is subcontract, the load = Days Out for the operation x Hours per Machine for the resource group.

-

Apply the production hours backwards, beginning with the operation due date and due hour. The first day applied is a special case, since the operation Due Time probably does not fall exactly at the end of the work day, so apply only the Due Hour as the maximum number of hours for the first day filled.

-

Calculate the setup load hours. Setup is always 0 if production has started, and for a subcontract operation.

- If relieving load by quantity :

Setup Load = Setup Standard - (Setup Standard * Setup Percent Complete)

- If relieving load by hours:

Setup load = Setup Standard - Setup hours to date

- Setup Load hours are zero if the operation is marked as Setup Complete or the setup hours to date exceed the estimate for setup.

- Apply the setup hours backwards, beginning where you left off with production.

Calculate Remaining : The Remaining Hours column is totaled according to the following equation: Remaining hours = Capacity - Total load

Print operation information and either setup or production load hours, or the sum of the two. Accumulate totals for each resource group and department.

At the end of each resource group, print the Capacity and Remaining totals also; likewise for each department. The Remaining hours are Capacity - Total Load for each bucket.