Hi all,

I take care of the all the machine scheduling for my shop, which is in the middle of transition from almost no formal scheduling to one that is completely in Epicor. There’s been a lot of progress but a main hiccup I’ve been having is scheduling jobs with lots of operations. The default finish to start scheduling assumes we will complete all parts on an operation before beginning the next one. However at our shop we move any parts finished at the end of a shift to their next work station. This leads to multiple instances of operations 10 through 40 or sometimes as far up as 70 being done at the same time. While that isn’t exactly a problem in itself, a few reports we run here need the scheduling dates to be accurate to the actual day their running.

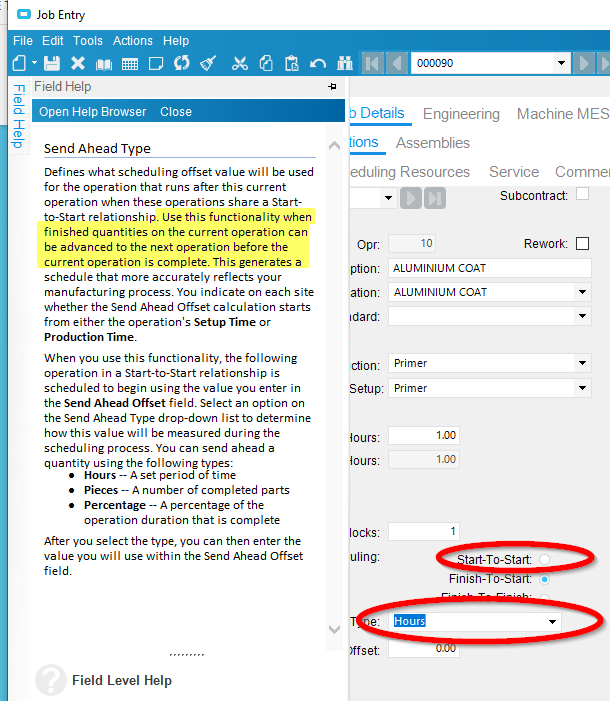

I originally tried to just manually change the dates for later operations , but this caused an error code for scheduling date ranges being out of parameters frequently. I looked into the other scheduling options but neither start to start or finish to finish make much sense for the way we move parts. I could be just misunderstanding the concept of them however, as I only have about 4 months of experience in production scheduling/supply chain and even less in Epicor experience. I’ve tried tackling this a couple different ways but I’m starting to think this problem is out of my wheelhouse, so if anyone knows something that might work or has any tips, I will greatly appreciate any input!

Thanks!