Our main project is to make the manufacturing side of the business go-live with Epicor in the new year so we seem to have a good handle on PO Suggestions and demand points/date from Manufactured parts. There is side of business that solely deals with purchased parts which is currently live. We are looking to start to bring in PO Suggestions for that site but are initial tests showed some odd behavior. Looking at one part in question PO suggestions were being raised with time phase showing we were several order multiplies above the min on hand value. I understood below minimum demand to be immediate i.e. today when running PO suggestions and SO demand being the need by date which is always the day of the order. We had 2 orders for the part and 2 open POs already in place but PO Suggestions kept raising new ones. Does Epicor out of the box not default to looking at total demand against total supply? The only way I got to stop POSuggestions from being raised way above the min on hand was to add a value to days of supply. Maybe it was the way Epicor was explained to us but this would seem to be a key field on the part (ok partplant) to easliy and quickly have Epicor do alot of thinking for but was never explained or identified with its importance.

Hi Matt - could you post what Time Phase shows? Sounds like timing might be an issue.

-Jeff

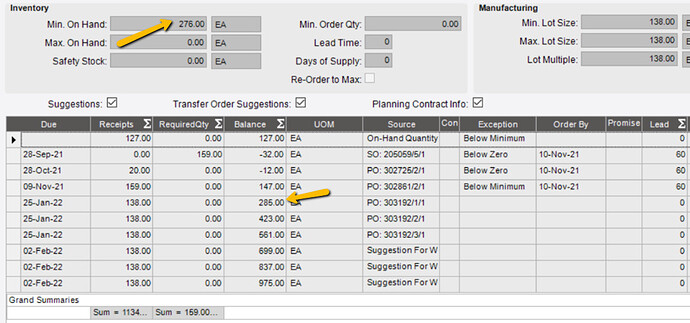

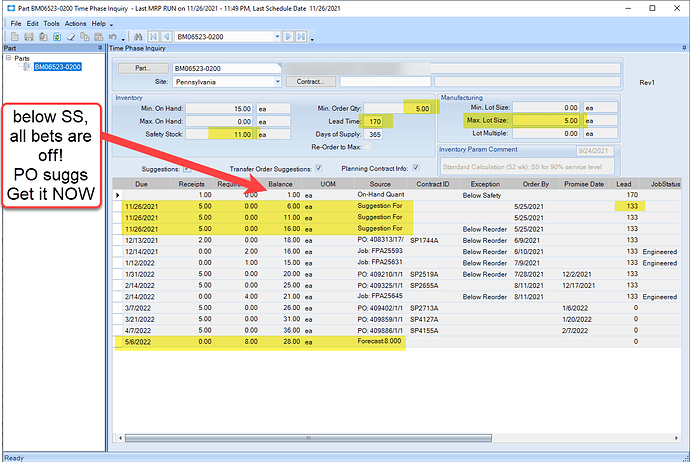

I took a screenshot of timephase when the issue existed. Seems to have gone since I set days of supply to 260

The 1st expected PO on 25th JAN shows us as being above min so I would have that no more POs would be issued.

Does that part have a long lead time? And do you have any future demand for it, like a forecast? Shame it’s a screenshot; it would be good to know what the rest of the Source column says for the Feb suggestions.

I think you need to put a lead time in for the part. If you have 0 for the lead time (shown in your snip) Epicor thinks you can get the part right now, so because you are below minimum right now and your issued PO has a due date months in the future, Epicor thinks you can get parts right now, so it makes another suggestion. Put in a lead time that is longer than the due date for the issued PO, generate suggestions, and see if you get another suggestion.

@Matt_Belshaw You have a lot multiplier of 138 set so you need 159, but you will get a suggestion for 138+138 plus the 12 you are negative which is over your min, but allowed since min is a level you can not dip below given all other parameters.

Unless there really is a box size of 138 I assume that would be 1 and your min on hand should be a multiple of the box size.

Days of supply is how often you want to place an order. 15, 30 or 60 would be normal. 260 seems long given only one SO.

Hi Brian

Thanks for the response. The part has a lead time at the supplier price list though. I am trawling through my documentation on what time priority. I may have to end up testing in TEST.

Hi Greg,

Thanks for the response. The lot sizing has been inherited from our other site which is much larger in size so do seem odd. RE: Days of supply, I understood that as MRP looking forward x number of days when calculating demand and supply so 260 is a default being a full calendar year. It would tie into your purchasing schedule so if you have days of supply as 5, which is our default, it looks forward 5 days to cover other demand. I don’t think 260 seems right but I’m testing further.

Thanks

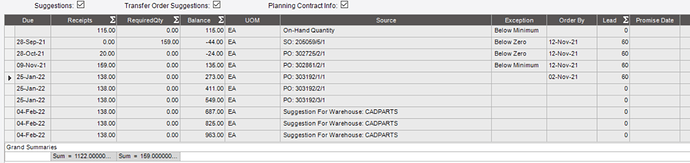

Hi Jeff. Leadtime is 60 days on Supplier Price list. No future demand as we are just SO and only a couple at the moment. Removed DOS ran suggestions again and here you go:

Just reaching out to @beth & @Nancy_Hoyt to see if they would like to review as a Friday afternoon challenge! No issue if that’s not possible

Thanks in advance

Matt

Hi Matt,

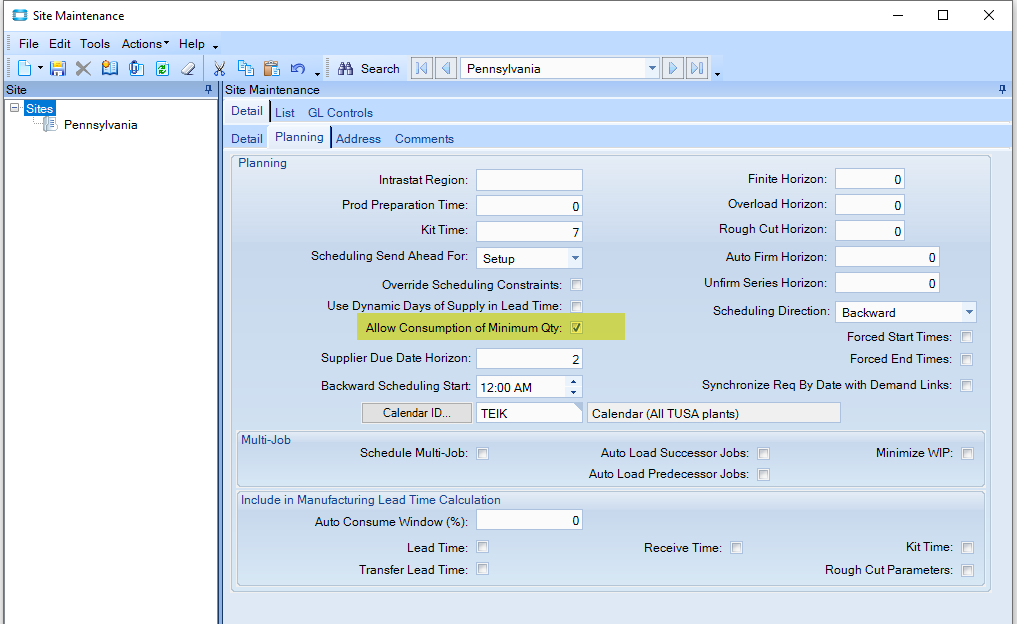

Getting PO suggestions to be believable is a worthy but monotonous feat with lots of testing as you know! Bad old dates combined with going below SS can cause havoc in getting sensible PO suggestions. At a minimum, I’d input better PO due dates. Also, I think Min OH gets treated like SS unless you check “allow consumption of minimum quantity” per screenshot. I have learned that DOS comes into play in that the system will try to ensure it is maintaining your MOH/SS over that timeframe. You have 0 in above screenshot. I recommend putting it out a bit longer than LT.

Nancy

Thanks Nancy. On the production main project we are dealing with jobs and lots of future demand which seems to work very well. On the current active site we are just buying and selling parts. Supply chain issues and poor management of SOs & POs are compounding the issues. I am trying to set something in place with a series of parameters that I know will work. I did experiment with days of supply on the part. Also experimented with Dynamic DOS. I just keen to understand the limitations. Also, just curious if you were to add a PO to a purchased part with a 60 day leadtime does Epicor, with default out of the box settings, look at future supply?

Regards

Matt

Hi Matt,

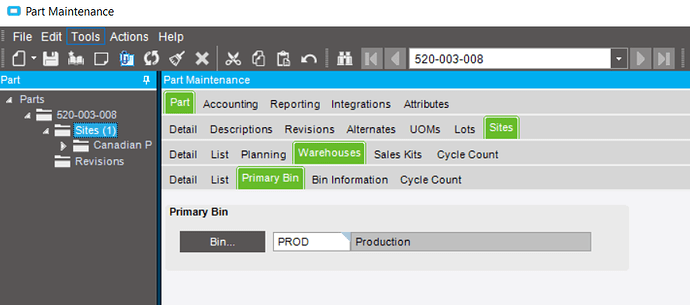

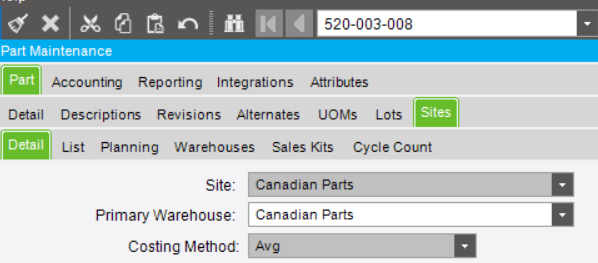

What is the Warehouse that is set as the Primary warehouse for this part? If it isn’t set as CADPARTS, then that may be why you are getting the suggestions. Take a look at the POs as well on the release tabs and the Sales Order to see that they all have the matching warehouse.

CADPARTs throughout SO & PO releases. This is on the part

Also, just curious if you were to add a PO to a purchased part with a 60 day leadtime does Epicor, with default out of the box settings, look at future supply?

Hi Matt,

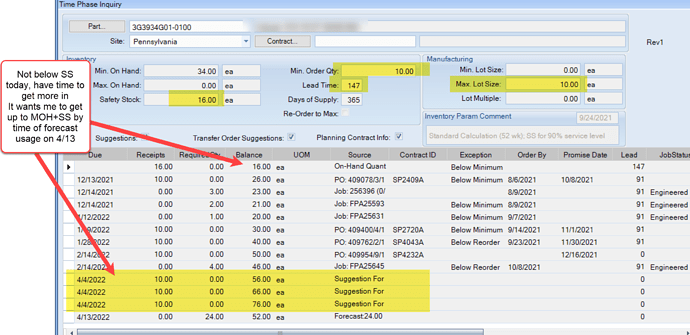

I don’t think that Epicor will count the cut future supply PO IF you are below SS (and possibly below MOH if you do not have allow consumption MOH checked on plant) OR IF you need it sooner. If you have locked PO quantity and date on PO release, you will get new PO suggestion to satisfy earlier demand. If you didn’t have those locked you would get PO change suggestion(s) to get enough in time.

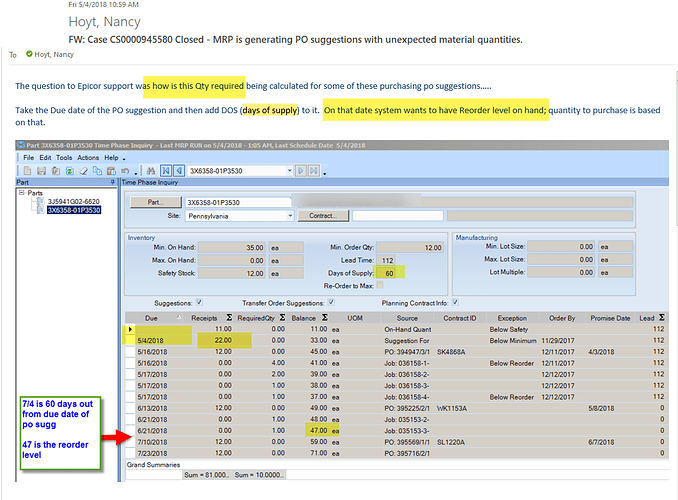

A few screenshots that might be helpful for what I’ve seen. First screenshot, back in 2018 had call with Epicor support “where the heck is this quantity being ordered coming from?” (just had an MOQ so why 22). From PO sugg date out to DOS (not dynamic, I haven’t used this) system works to get quantity.

Next 2 screenshots, a couple of parts today. Second pict below SS but above MOH, getting PO suggestion to buy immediately even though I have many incoming POs. Third pict we have QOH above both SS and MOH… (note, We use forecast to put load on system far out that we base on expected average usage)

Nancy

Thanks Nancy. There is alot of info there to review.

It seems checking either DDOS or allow consume minimum stops unnecessary PO suggestions. I will will play with this some more.

Is there a default bin? Are you using forecasting? It doesn’t appear that you are since there isn’t a demand being created for it.