Does anyone have some examples of a configured product with a kit of spare parts underneath it. On the same line preferably as its price is included with the configured items. I’m trying to figure out how to do this without using several line items on a sales order for customer experience and our shop floor personal.

So you want the configurator to generate an additional line item on the order separate of the configured line?

well it would be under the same line but a kit with that configuration. It can also be another line item if that works just not sure how to make that work and build that up.

Could you do this with Reporting? Go ahead and have all the lines internally but have your customer facing documents and picking report as a different report style that gives everyone what they want. Might be less work than trying to bend the system to our will.

We do something like this… some lines with our configuration are intended to be assembled in a “main kit” and others are options and if part of the configuration must be separate line items on the order so that we can properly charge the customer and make sure the revenue goes to the right place. If this is what you want, I could help you.

@Mark_Wonsil I like your idea also. If it’s merely for cosmetic reasons, the report might be easier to manipulate.

that would be wonderful if your able to provide guidance. i think that might work for us.

Long story short: we created a UD Column on OrderDtl and QuoteDtl called IsParentConfig and ConfigGUID. The configured line would be checked as the parent and all lines associated to that config would get the same GUID. We do this using UD Methods that are fired from the Document rules. Essentially, it uses the SalesOrder and Quote service and fires the appropriate methods used when creating new lines.

Hi Devin,

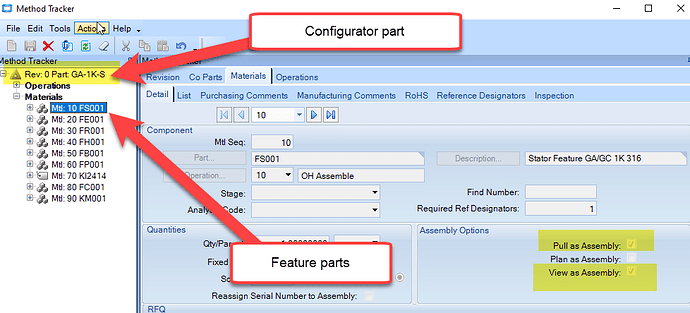

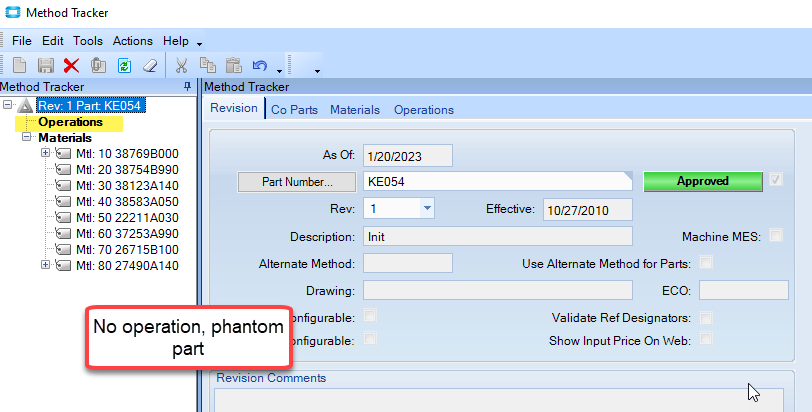

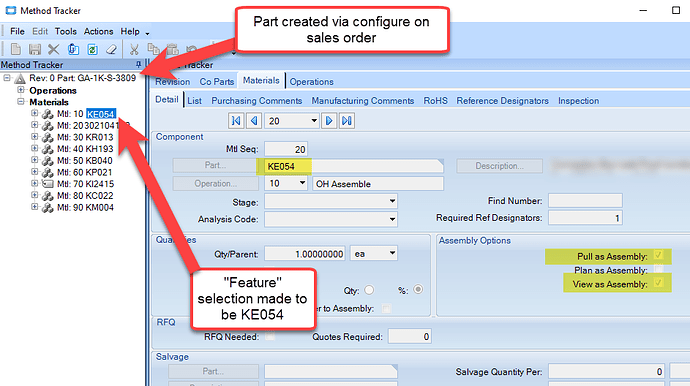

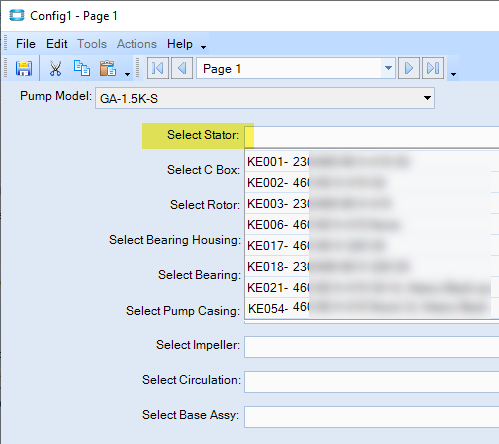

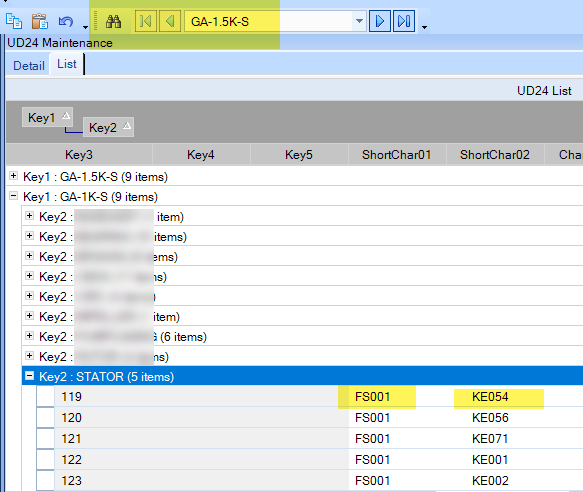

Let me add one other idea. Our (very basic) configurators are designed with what we call “Feature” part numbers. These are placeholder phantom parts that get replaced with “real” part numbers based on user configuration selections. We store our mapping of feature parts to real parts in a UD table. You could do similar and have user select spare parts configurator selection and then do a swap in of real part number, likely a phantom part if no ops needed. If the feature is left in, perhaps provide part description on it as NONE or something like that to communicate to ops no spare parts. The phantom spare parts kit would become a pull as assembly part on the method/job. Here’s an example of a phantom part we would swap in for a feature placeholder part based on user selection:

At sales order entry, pick option:

Thanks for the suggestion but i dont need a job for the spare parts as it is only needed to be pulled from inventory and put in a box.

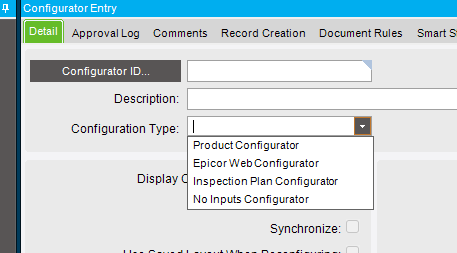

what do i select for sales kit \

it is a product configurator.