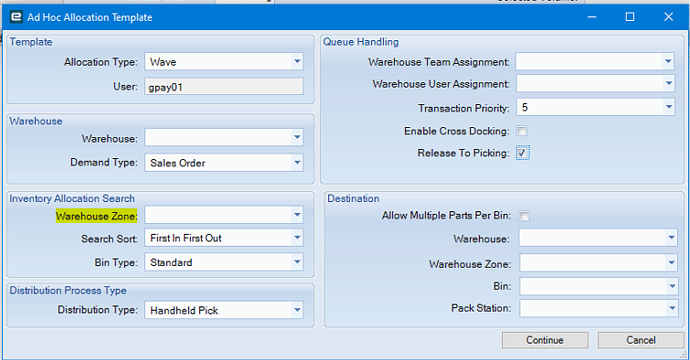

Hi, I have some code attached to a Data Directive to reserve stock from the Primary warehouse of a Part Code as it was entered into the Order. This was fantastic until we started running out of space in the warehouse and we needed to stock in Separate Warehouses.

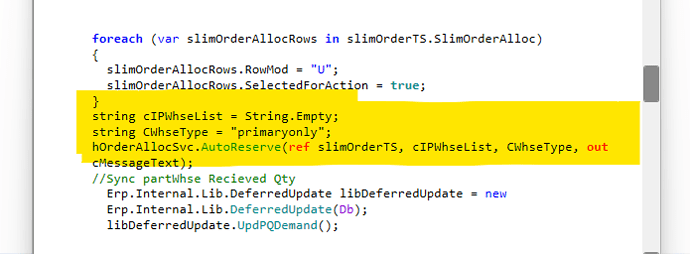

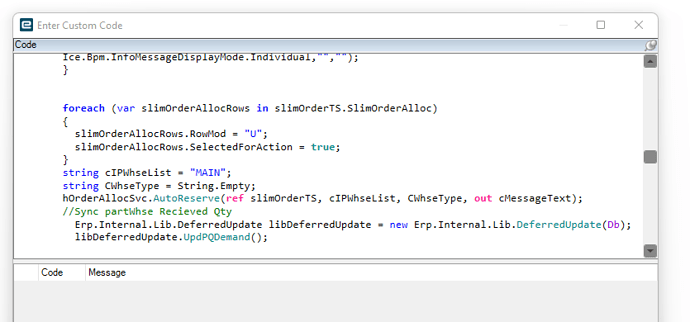

This Part of the code is now the issue, where CWhseType state primary only, i would like to specify 3 different warehouse codes instead. We have too many warehouses to allow all Reservations from all warehouses using String.Emtpy;

I have attached all the code below.

var hOrderAllocSvc = Ice.Assemblies.ServiceRenderer.GetService<Erp.Contracts.OrderAllocSvcContract>(Db);

using(hOrderAllocSvc)

{

foreach(var orderRelRow in (from row in ttOrderRel where row.RowMod == IceRow.ROWSTATE_ADDED || row.RowMod == IceRow.ROWSTATE_UPDATED select row))

{

int orderNum = orderRelRow.OrderNum;

int pageSize = 0;

int absolutePage = 0;

bool morePages ;

DateTime resultDate;

bool newReserveStkVal = orderRelRow.ReserveStock_c;

bool oldReserveStkVal = false;

if(orderRelRow.RowMod == IceRow.ROWSTATE_UPDATED)

{

oldReserveStkVal = (from row in ttOrderRel where row.RowMod == IceRow.ROWSTATE_UNCHANGED && row.Company == orderRelRow.Company && row.OrderNum == orderRelRow.OrderNum && row.OrderLine == orderRelRow.OrderLine && row.OrderRelNum == orderRelRow.OrderRelNum select row.ReserveStock_c).FirstOrDefault();

}

//string orderNumWhereClause = “OrderNum = '” + orderNum.ToString() +"’";

string orderNumWhereClause = “OrderNum = '” + orderNum.ToString() +"’ AND OrderLine = " + orderRelRow.OrderLine.ToString() + " AND OrderRelNum = " + orderRelRow.OrderRelNum.ToString() ;

bool reserveFlag = oldReserveStkVal == false && newReserveStkVal == true;

bool unReserveFlag = oldReserveStkVal == true && newReserveStkVal == false && orderRelRow.RowMod == IceRow.ROWSTATE_UPDATED;

if(reserveFlag || unReserveFlag)

{

var orderAllocDS = hOrderAllocSvc.GetListFWB(orderNumWhereClause,pageSize,absolutePage,out morePages);

var orderAllocTableSet = hOrderAllocSvc.OrderAllocationGetRows(orderAllocDS, 0);

bool opCalcFulfillOnSearch;

hOrderAllocSvc.GetCalcPref(out opCalcFulfillOnSearch);

hOrderAllocSvc.SetCalcPref(opCalcFulfillOnSearch);

bool opFWBFulfillFromDemandWhseOnly;

hOrderAllocSvc.GetFWBFulfillFromDemandWhseOnly(out opFWBFulfillFromDemandWhseOnly);

string cMessageText = String.Empty;

//Reserve

if(reserveFlag)

{

Erp.Tablesets.SlimOrderAllocTableset slimOrderTS = new Erp.Tablesets.SlimOrderAllocTableset();

foreach(var orderAllocRow in orderAllocTableSet.OrderAlloc)

{

decimal unreservedInventory = orderAllocRow.UnreservedInventory;

decimal ourReqInv = orderAllocRow.OurReqQty ;

//this.PublishInfoMessage("unreservedInventory: " + unreservedInventory.ToString()+ "ourReqInv: " + ourReqInv.ToString(),Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual,"","");

bool makeDirect = (from row in Db.OrderRel where row.Company == orderAllocRow.Company && row.OrderNum == orderAllocRow.OrderNum && row.OrderLine == orderAllocRow.OrderLine && row.OrderRelNum == orderAllocRow.OrderRelNum select row.Make).FirstOrDefault();

if(makeDirect == false)

{

if(unreservedInventory >= ourReqInv)

{

orderAllocRow.SelectedForAction = true;

orderAllocRow.RowMod = "U";

Ice.IceRow newRow = slimOrderTS.SlimOrderAlloc.NewRow();

newRow["Company"] = orderAllocRow.Company;

newRow["SelectedForAction"] = true;

newRow["DemandType"] = "Order";

newRow["JobNum"] = orderAllocRow.JobNum;

newRow["AssemblySeq"] = orderAllocRow.AssemblySeq;

newRow["MtlSeq"] = orderAllocRow.MtlSeq;

newRow["OrderNum"] = orderAllocRow.OrderNum;

newRow["OrderLine"] = orderAllocRow.OrderLine;

newRow["OrderRelNum"] = orderAllocRow.OrderRelNum;

newRow["FulfillmentSeq"] = orderAllocRow.FulfillmentSeq;

newRow["TFOrdNum"] = orderAllocRow.TFOrdNum;

newRow["TFOrdLine"] = orderAllocRow.TFOrdLine;

newRow["RowMod"] = "A";

if (DateTime.TryParse(orderAllocRow.DoNotShipBeforeDate.ToString(), out resultDate))

newRow["DoNotShipBeforeDate"] = resultDate.ToShortDateString();

if (DateTime.TryParse(orderAllocRow.DoNotShipAfterDate.ToString(), out resultDate))

newRow["DoNotShipAfterDate"] = resultDate.ToShortDateString();

slimOrderTS.SlimOrderAlloc.Add(newRow);

}

else

{

errorRecList.Add(Tuple.Create(orderRelRow.OrderLine.ToString(), orderRelRow.OrderRelNum.ToString()));

}

}

}

if(slimOrderTS.SlimOrderAlloc.Count > 0)

{

hOrderAllocSvc.CheckDates(ref slimOrderTS, out cMessageText);

if(!string.IsNullOrEmpty(cMessageText))

{

this.PublishInfoMessage(cMessageText ,Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual,"","");

}

foreach (var slimOrderAllocRows in slimOrderTS.SlimOrderAlloc)

{

slimOrderAllocRows.RowMod = "U";

slimOrderAllocRows.SelectedForAction = true;

}

string cIPWhseList = String.Empty;

string CWhseType = "primaryonly";

hOrderAllocSvc.AutoReserve(ref slimOrderTS, cIPWhseList, CWhseType, out cMessageText);

//Sync partWhse Recieved Qty

Erp.Internal.Lib.DeferredUpdate libDeferredUpdate = new Erp.Internal.Lib.DeferredUpdate(Db);

libDeferredUpdate.UpdPQDemand();

if(!string.IsNullOrEmpty(cMessageText))

{

string unReservedMsg = "0 Demand record(s) reserved";

if(cMessageText.Contains(unReservedMsg,StringComparison.OrdinalIgnoreCase))

{

this.PublishInfoMessage(cMessageText ,Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual,"","");

}

}

}

string exceptionMsg = "";

string vSubject = "";

if(errorRecList.Count > 0)

{

exceptionMsg = " Order Release has not been reserved ";

vSubject = " Sufficient inventory is not available to allocate some order releases of order number: " + orderNum.ToString();

}

foreach(var errorRecord in errorRecList)

{

exceptionMsg = exceptionMsg + Environment.NewLine + "Order Line: " + errorRecord.Item1 + " Order Rel: " + errorRecord.Item2;

}

if(!string.IsNullOrEmpty(exceptionMsg))

{

//if(!string.IsNullOrEmpty(cMessageText) && (callContextClient.AssemblyName.StartsWith("Erp.UI") || callContextClient.AssemblyName.StartsWith("Ice.UI")))

this.PublishInfoMessage(exceptionMsg,Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual,"","");

//Send mail with exception details and throw message

var mailer = this.GetMailer(async: false);

var message = new Ice.Mail.SmtpMail();

exceptionMsg = exceptionMsg.Replace(Environment.NewLine,"<br>");

message.SetTo(vToEmail);

message.SetFrom(vFromEmail);

message.SetSubject(vSubject);

message.SetBody(exceptionMsg);

message.IsBodyHtml = true;

mailer.Send(message);

}

}

if(unReserveFlag)

{

//UnReserve

foreach(var orderAllocRow in orderAllocTableSet.OrderAlloc)

{

bool makeDirect = (from row in Db.OrderRel where row.Company == orderAllocRow.Company && row.OrderNum == orderAllocRow.OrderNum && row.OrderLine == orderAllocRow.OrderLine && row.OrderRelNum == orderAllocRow.OrderRelNum select row.Make).FirstOrDefault();

if(makeDirect == false)

{

orderAllocRow.SelectedForAction = true;

orderAllocRow.RowMod = "U";

}

}

if(orderAllocTableSet.OrderAlloc.Exists(x=> x.SelectedForAction == true))

{

hOrderAllocSvc.Unreserve(ref orderAllocTableSet,out cMessageText);

//Sync partWhse Recieved Qty

Erp.Internal.Lib.DeferredUpdate libDeferredUpdate = new Erp.Internal.Lib.DeferredUpdate(Db);

libDeferredUpdate.UpdPQDemand();

//if(!string.IsNullOrEmpty(cMessageText) && (callContextClient.AssemblyName.StartsWith("Erp.UI") || callContextClient.AssemblyName.StartsWith("Ice.UI")))

if(!string.IsNullOrEmpty(cMessageText))

{

this.PublishInfoMessage(cMessageText ,Ice.Common.BusinessObjectMessageType.Information, Ice.Bpm.InfoMessageDisplayMode.Individual,"","");

//Send mail with exception details and throw message

var mailer = this.GetMailer(async: false);

string vSubject = "Order UnReserve process failed with some errors for order number: " + orderNum.ToString();

var message = new Ice.Mail.SmtpMail();

cMessageText = cMessageText.Replace(Environment.NewLine,"<br>");

message.SetTo(vToEmail);

message.SetFrom(vFromEmail);

message.SetSubject(vSubject);

message.SetBody(cMessageText);

message.IsBodyHtml = true;

mailer.Send(message);

}

}

}

}

}

}