This is somewhat similar to this topic: How to handle job material qty required based on total to be made - #7 by ckrusen

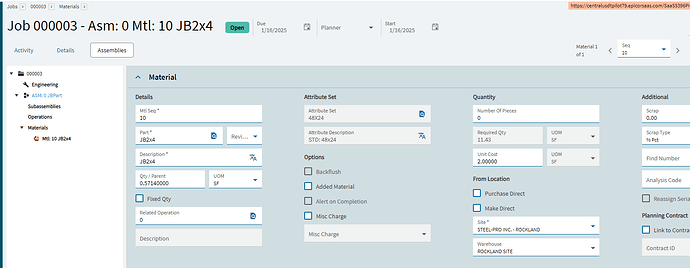

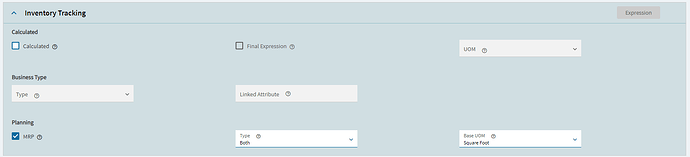

Using the response from @timshuwy on the linked topic seems to work for non AUOM parts, but we’re having some difficulty trying to extrapolate that out for the AUOM parts we have.

To break down the issue, we have sheets of material, that we can fit X amount of parts in, so like the linked topic, once you go over a certain qty of parts, you need another piece of material. This is somewhat complicated by us planning to use a section of the full sheet.

As an actual example, say we have a quote with the following quantities:

20

25

50

75

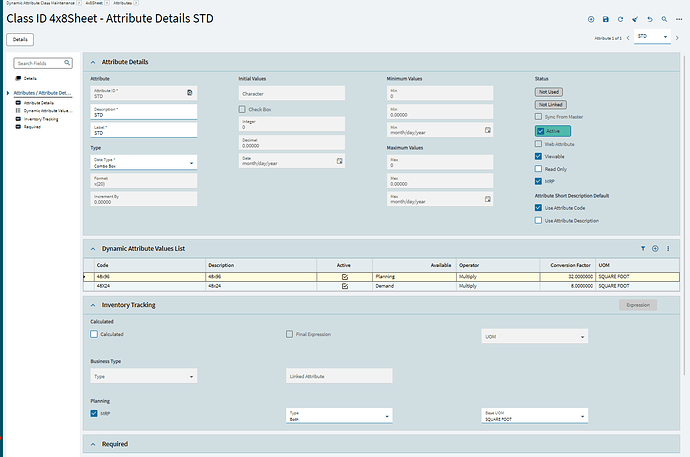

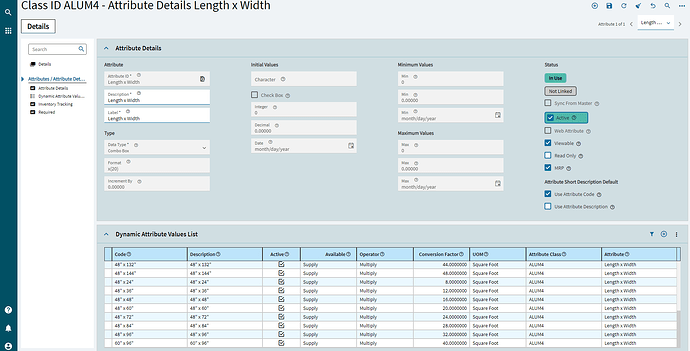

Based on how the part is setup, we plan on using a 48X24" (8 SqFt) section (what we call a blank) of a 48X96" (32 SqFt) sheet. These different possible allowed sizes, typically in 12" sections, are where the AUOM come in. This 48X24" blank can fit 14 parts. So once we go over to 15 parts, we need another 48X24" blank.

Based on that, what we’re trying to get to is that the quote knows that it needs to assign material in 8 SqFt amounts in this case. So what I would expect is:

20/14 = 1.42 -----> 2 Blanks (16 SqFt of material)

25/14 = 1.78 -----> 2 Blanks (16 SqFt of material)

50/14 = 3.57 -----> 4 Blanks (32 SqFt of material)

75/14 = 5.35 -----> 6 Blanks (48 SqFt of material)

Seemingly no matter how I try setting this up, it seems to be taking the 8/14 (8 Sqft/14 parts = .5714 SqFt per Part) factor and doing one step of rounding at the very end to the next SqFt, but not the required quantity in increments. These are the results I am getting:

20 * .5714 = 11.428 ----> 12 SqFt (1.5 Blanks)

25 * .5714 = 14.285 ----> 15 SqFt (1.875 Blanks)

50 * .5714 = 25.570 ----> 26 SqFt (3.25 Blanks)

75 * .5714 = 42.855 ----> 43 SqFt (5.375 Blanks)

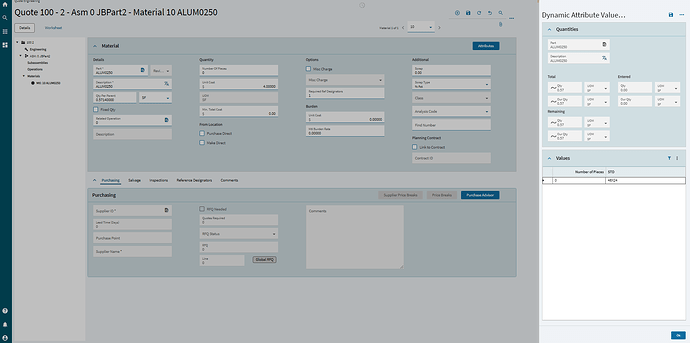

Anyone have any suggestions for how this could be setup to work as we would expect it to?