We have been using Epicor cycle counting for a few years now. For some reason, the number of parts in the count sheets has suddenly increased to three or four times the usual number of parts to count each day. Can anyone explain why, or even better, how to arrange things to evenly distribute the number of counts we’re performing each day?

Epicor will try to enforce the ABC Code Count Frequency for each part. To start someone may have changed the Count Frequency for the ABC code or someone ran the ABC Calculation which assigned different ABC Codes (which should be ok if ‘usage’ has actually changed).

Either way, Epicor will try to catch you up to the Count Frequency of the ABC code for each part.

BTW - the distribution should be pretty even within each period.

Thanks much for the response. I can confirm that the count frequencies have not been changed, nor has the ABC Calculation been run since last summer. Any other thoughts? We did stop counting for a few weeks very recently. Is it possible those parts have just been reassigned to current count dates? If so, how does Epicor decide where to put those parts? And, when would you expect the number of parts on the daily count sheets to get back to our usual quantities?

I should have said the way we stopped counting recently was to simply delete the weeks from the overall schedule. We did not move the relevant parts to new count dates at that time.

So since Epicor tries to catch you up and if you missed counts (cycles canceled) then when you generate again it will try to catch up. So say your period is 1 month with 20 cycles and 10 cycles were missed then the remaining 10 cycles will probably double.

As for the order, that depends on if your Cycle Count option is random or repeat, and even then it’s not that predicable.

BTW - the relationship between the cycle frequencies, # of periods and # of cycles per period will affect the number of parts. For instance, Quarterly periods vs Monthly periods will produce different results, plus if and when you rerun the ABC Calculation process.

For instance, one of my clients have Quarterly Periods and they recalc their ABC Codes at the beginning of each quarter, BEFORE Auto Selecting Parts. Another client only recalcs ABC codes Annually and have Monthly periods.

Most likely, my Quarterly configured client would not see has dramatic of a spike as my Monthly client, but that also depends on WHEN during the period the cycles were canceled/deleted.

Regardless, Epicor will attempt to select the correct number of parts to keep you compliant with your Count Frequencies and there isn’t a good way to adjust it, short of manually removing parts from cycles, but know that the next Auto Select Parts will try to make up for that.

To attempt to ‘flatten the curve’ from my above example, you could remove half of the missed parts (5) to easy the count burden, but those will get caught up later.

Unfortunately, I have not worked out the exact science of how it works, but in my experience, Epicor seems to follow the rules you put in and rarely misses.

Not sure that helps much, but if you were my client, I would advise to go with it and I’m pretty confident it will ease up in the future.

Thank you again for all the information. We were running with quarterly periods, but our Epicor consultant had us set up 12 months of weekly periods starting last July. We have been re-calculating ABCs about once annually, and we are due to re-calculate now. Maybe that will even out the daily counts. Or since we have no periods in the system beyond the end of June, is that going to squeeze counting for all our inventory parts into the next two months? I would really like to get everything synced to the calendar again. Should we be setting up the weekly periods for the balance of this year now, re-calculating ABCs, and then doing this all at the same time going forward?

Yes, weekly periods would have this affect, and weekly periods will keep you very close to the ABC Count Frequencies, but if you miss a few weeks, the next week will try to catch up both those weeks.

If the number of parts this week was three times as much a normal, I would expect things to settle down the next week (period), maybe not completely back to normal, but it should just spike.

As far as I have been able to determine the part selection is based per period, the count frequency is completely date based, so it grabs everything that is due for the entire period and tries to then evenly distribute across the cycles.

Recalc of ABC codes can affect the number of parts per period, especially if you now have more parts or your overall usage has gone up since that would push more parts into A (higher frequency).

You can continue with weekly periods, nothing really wrong with that, it’s a per company preference. It does keep you tigher with your count frequency rules.

When you create your periods doesn’t matter, it’s the timing of the Cycle part selection that matters, and I would do that AFTER recalculating ABC codes, because the new ABC assignment applies to part selections done following the reassignement, it is not retroactive.

The frequency of running the ABC Code Recalc really has more to do with the number of new parts that are created and how often your usage shifts. I think once a quarter is best, so you have 4 opportunities a year to add those new parts to the cycle frequency as well as adjust for seasonal usage changes.

In short, you are probably fine with everything you are doing, you just need to catch up and weekly periods are not forgiving as you need to catch up any loss within the next period. I say continue as you have unless the next period is still out of wack, but I doubt that will happen.

as @Rick_Bird mentioned, there are two ways to select… Random and Repetitive. This sometimes feels backwards, but “Random” selection will return more predictable results, MAINLY because you can also choose the maximum number of parts to be counted per period. Note that because you enter the count, you could end up counting too many (or too few) per your cycle counting rules. I typically suggest that you go with “random” and set the numbers slightly higher than needed. See the attached spreadsheet that helps you calculate how many to count.

Also, for simplicity sake, I normally recommend Monthly cycles, UNLESS you count your A items more often than 12 times per year. If your A items are only counted 4 times per year, then you can have quarterly cycles… but that just seems too long for my preference.

Cycle Counting part count Model.xlsx (11.5 KB)

Hi, Tim. In the string above, you state that “‘Random’ selection will return more predictable results, MAINLY because you can also choose the maximum number of parts to be counted per period”. Where do we actually load the maximum number of parts to be counted per period? We cannot seem to locate the field(s). Thanks!

Can anyone advise where we set the maximum number of parts to be cycle counted per cycle/day?

Hi,

Wondering if you ever found an answer to this?

Nope. We are often still having to delete dozens of parts from each day’s count sheets to get the work to a manageable level for our warehouse. If you ever find an answer, I would love to have it!

Thanks, Jackie

Darn, thanks for answering! I will see if I can find anything and let you know if I get lucky.

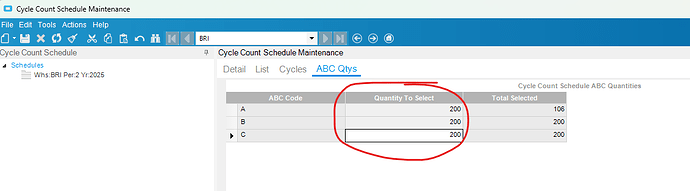

Delete the existing schedule in the Cycle Count Schedule Maintenance screen. Change the Cycle Count Selection Method to RANDOM in site config. Create a new schedule is Cycle Count Schedule Maintenance, then on the ABC Qtys tab, the quantities to select fields should be editable for your ABC Codes.

We are currently playing around with the settings to try to get 90 to 100 parts to cycle count per day.

I actually had some luck with what you are trying to get.

This set up 60 parts per day as I intended.

See my notes below -

| To select amount of parts per cycle - | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|

| Within the Cycle Count Schedule Maintenance click the ABC Qtys tab | |||||||

| Decide how many parts you want to count per day within your select date range. | |||||||

| Example - | |||||||

| I did date range from 3-5-25 to 4-30-25 which is a total of 41 working days | |||||||

| I decided MFG would count 60 parts per day | |||||||

| This equals 2460 parts | |||||||

| Determine how many parts you want to select per ABC code. | |||||||

| A = 5% | 123 total | ||||||

| B = 15% | 369 total | ||||||

| C = 80% | 1968 total | ||||||

| 2460 |

if you look up the post earlier in this post (Quantity of Parts to Be Cycle Counted - #8 by timshuwy) you will find a spreadsheet that i have used over and over again to determine what the minimum daily/monthly count should be to count all your parts every year. You can populate your count of part numbers, A/B/C percentages, and the number of counts per year for each, and the spreadsheet does the math and recommendations.

Thank you, thats helpful!

Ugh! We have our site config set to RANDOM. But when I create a new schedule, the ABC values are all greyed out and I cannot set the quantities desired. So I am still getting way too many parts to count each day. Sure wish I could figure this out!

Figured out that there is a setting for “random” at the site config level and also a setting for “random” at the warehouse level (in warehouse setup). The warehouse overrides the site config setting. Looks like after years of struggling, we finally got this to work as needed!