We’re having an issue with jobs showing short that actually aren’t. I have a job that was showing clear yesterday and I released it. Today it shows short. When I look at the parts that are showing short in time phase - they are there and there is nothing ahead of the job in question. This is causing a real problem as we’re already fighting the battle to get production to “trust” the system… Any ideas?

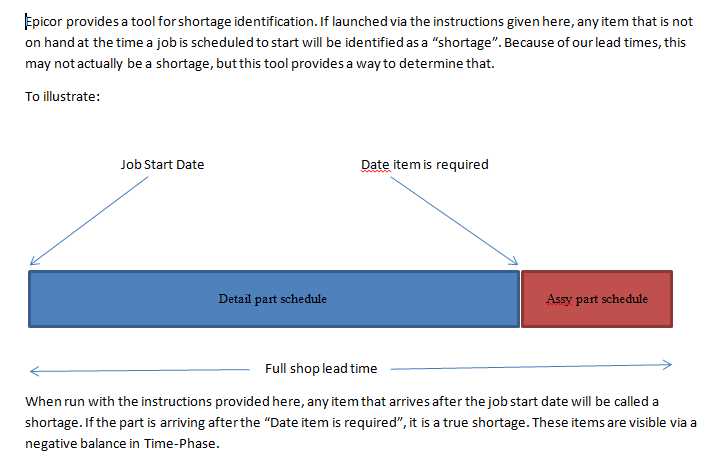

A “shortage” in Epicor is an item that will not arrive before the start date of the job. If you have long lead times, that can be a bit misleading. Here is a little chart I made to help understand it, I actually put it in our work instructions for shortage generation.

If the part arrives after job start, but before the operation it is needed on is due to begin, this can happen. I actually like this, it keeps the shortage list “aggressive”. That’s good, because a true shortage is something we want to avoid at all costs. I’d rather check the part in time phase than just trust the data.

Admittedly, this could be an issue if you have a large database of items. I am blessed in that regard. If we had to look through 1000 fake shortages to find the 30 real ones, I’d probably have to come up with a different method.

The items that are showing short for me are actually in stock now - with no other jobs scheduled before them.

Can you snip a time phase screen and post it here?

Have you regenerated the Production Planner Workbench, and what settings do you use to launch it?

This is a topic of high interest to me, as we are finalizing our shortage identification process in Epicor.

Now I think I’m seeing things… I ran the process again…even though it runs overnight and should have been updated. Now the system is giving priority to unfirm MRP jobs that show a start date earlier than my released job. I thought firm and released jobs would get the priority in allocation of material?

Everything is driven by date. If you want your plans to run after your jobs, you have to make sure the plans schedule properly.

Might be time to look at your demand for the item, and see if it is reasonable. If you are under lead time, you are going to see a LOT of this.

Sadly almost everything is under lead time… and current component shortages aren’t helping… Ok – I’ll start pushing on the scheduling side of this…

Thanks for your help!

Don’t lie to the system. It will tell you to do everything possible to meet your demand. As an instructor told me early on with my Epicor training, MRP is “relentless”.

If you put a demand signal in Epicor that you know cannot be met, do not expect actionable results. If you know that you won’t meet that schedule, don’t expect Epicor to magically solve that problem.

I agree completely! I just have to convince others who put said demand in the system and then drive the rest of us insane as we chase our tails trying to make it happen. I think I will forward your comment to my biggest challenges – couldn’t hurt!

I fight the same battles every day. But, I also have an enormous amount of data that shows that when we control material in Epicor, our inventory reduces.

Tell whoever is building demand that it sure is a lot easier to ship a million dollars worth of product when you plan two million. Hopefully, they’ll understand what you mean. ![]()

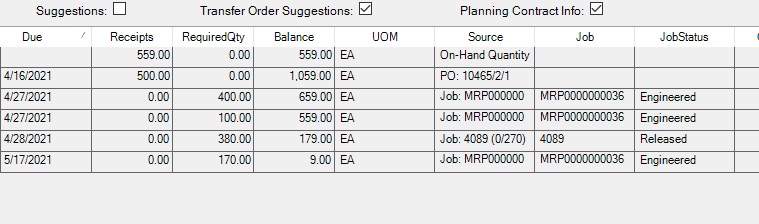

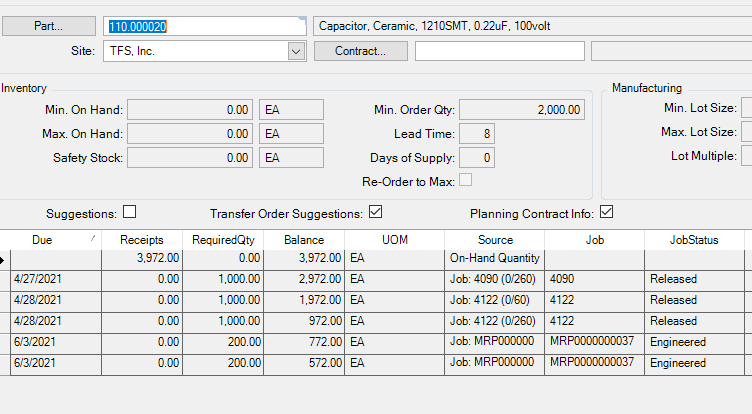

We’ve “fixed” a lot of issues with how we were scheduling jobs and running MRP. We’ve also started allocating material to released jobs. So I can’t wrap my brain around why I’m seeing things showing as shortages in the production planner workbench when there is material in stock. Here is the time phase on a part that is showing as a shortage for job 4122. I’m stumped.

Keep in mind that if you specify the operation that consumes a part, Epicor will still use the job start date (and not the date of the item’s operation) as the trigger to define “shortage”.

I typically evaluate parts in Production Planner Workbench, look at the part in TIme Phase, and turn off suggestions. If there is a negative balance anywhere, that is our definition of “shortage”.

NOT INTUITIVE. Creates a lot of extra work.

We do the same… I always turn off suggestions in Time Phase. I created a BAQ to grab the parts shortages from the PPW and to calculate what’s on order and if there will still be a shortage after the parts are received and we use that as a quick glance and then work through the buyer workbench

I have (for the time being) abandoned using Production Planner Workbench for shortage identification. Since I was going to Time Phase to validate the shortage anyway, I’ve begun using the Time Phase Material report. At least it shortens the search, the shortages are listed, and the time-phase information is included in the report.

Saves the 2-3 hours it took to go through and validate Production Planner Workbench against Time Phase, and seems to provide the same information.

We’ve had some success with PPW if we use the Fulfillment Workbench to allocate the parts to the jobs when we firm or release them. It’s an extra step but it is giving us the visibility we need in the Production Planner Workbench. We had mistakenly thought that “reserving material” would do the trick - it doesn’t. I’m honestly not sure why there is even a “reserve” function because it doesn’t seem to actually do anything.

I see that you are running 10.2.600.13, @WendyB. Do you know if any major issues were fixed with PPW after 10.2.200? That’s the version that we are running and we are finding that even allocating or releasing for pick does not give us the visibility that we need. However, we are having the opposite problem, i.e. job material demand exceeds on-hand supply, but PPW does not show any shortage, even as of the unfirm jobs’ start dates. It seems that the only way that on-hand material is being considered unavailable is to issue the materials to the other jobs. I was presuming that we were missing a key step in the process, but now I am not so sure after reading the posts by you and @Gil_V. I’ve search EpicCare but have not been able to find anything helpful.

Part of this might be the flags chosen when running Production Planner Workbench Generation. If you don’t tell the system to ignore future PO’s, it does not identify the shortage.

Frankly, the flags on the launch screen are not very well explained in the help file - or anywhere in the product documentation - at least that I have been able to locate. I have yet to find the right combination of settings to answer the simple question “what will we run out of in the current demand/supply schedule”?

I just want to know what we’re going to run out of. Seems like a simple enough thing to generate, for the time being I’ll stick with Time Phase Mat’l report until I find something better.

Yes - making sure which flags are checked is critical - and no - it’s not explained well at all. But we ignore future po receipts and expedite suggestions and we include released jobs – those are the only things we check on the PPW Process