I am getting very frustrated with PO suggestions. They should make life way easier, and it seems so basic, but they do not work right. I need some real world help on why my problem keeps happening or maybe different settings I need to make them work better.

Basically, I will get a suggestion, that I almost agree with. But it will split up a part into 2 releases. Some of those part simply do not make sense to split up because they are freight shipped and should be shipped together. So I Order from suggestion, but manually combine the releases. and tomorrow, we will see the same suggestion except with only one of the release qtys.

Example: we have a freight shipped item, that showed us a suggestion for 17 units, 1 on 1 release, and 16 on another. During the suggestion review process, our purchaser removed the release of 1 and added to the release of 16, so it would order 17 units on the same (and earlist due) release.

Now, that part continues to come up on the suggestion list for 16 units. I cannot get rid of it.

Consultants have said it is due to due dates which we have adjusted multiple times to try and fix, and it has not worked.

This part does not have a min max, has a days of supply of 20, has a lead time of 45 days and is not buy direct. But all of that in my mind shouldn’t matter. 17 of them are on order, set to be in before the due date. Why is it even on the suggestion list?

I guess I don’t understand why the system doesn’t understand that there are enough of this part on order, due to be here in time, and to stop giving me suggestions on it. I kind of want it to stop giving me releases even, and just order the part on the same release. I also almost do not care about change po suggestions which might be in play.

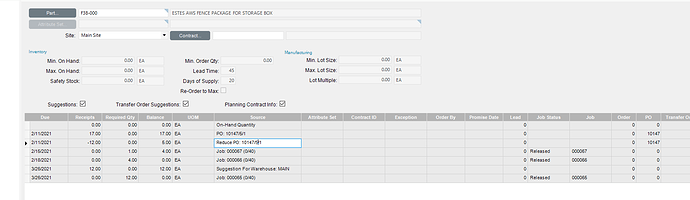

This is the time phase report for my part:

any suggestions from other buyers out there to make this work better?