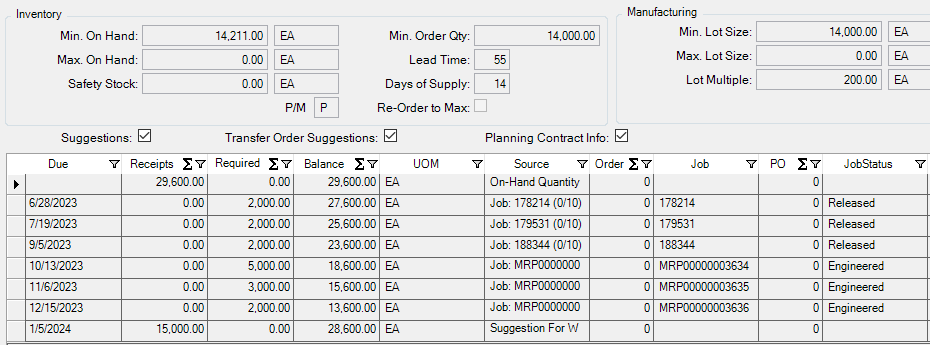

Here is an example of a part that drops below minimum on hand on 12/15. MRP creates a suggestion to order today with a 55 day lead time which makes the due date 1/5/24. Is there any way to make the suggested due date 55 days from the date that we go negative instead of 55 days from today?

Double check the supplier calendar. I think the lead time is for business days, so if your supplier is set to be available 5 days per week with some holidays, the 55 business days lead time equals somewhere around 84 calendar days, which fall not far from 1/5/24 as suggested by the MRP.

From the “Lead Time” field help:

Thanks for the response. I think the due date makes sense - my real question is - Is there a way to tell MRP to not suggest the purchase immediately. In the example we do not go below min on hand until December 15th - so why would it not suggest the purchase at that point instead of immediately? This part has no safety stock and I have consume min on hand set to true on the site configuration record.

The lead time of 55 days means you need to order it that far in advance of when you will run low so you don’t run out. Otherwise you would be out of stock for the amount of time it takes to get it from the supplier (i.e. 55 business days). If you don’t want to order until you hit the min, set the lead time to zero.

So I changed the lead time days to 0 and now the suggestion has an order by date and a due date of 12/15. That makes the order date correct, but it will require the buyers to manually calculate the lead time for the due date. So There is no way to add the lead time automatically with an OrderBy matching the date it goes below minimum? (in this case that would mean an order by of 12/15 and a due date of 3/1/24 with a 55 day lead time(11 weeks)

Try using safety stock instead of min on hand. Set safety to 14,211 and min on hand to 0.

That acts the same as the min on hand - it calls to order immediately. If I put the lead time back in then it has a due date of 1/8/24.

you are looking at time phase… so the DUE date is the date it will ARRIVE

but if you look at PO Suggestions, there is an ORDER BY date, and this takes into account the lead time. THIS is where the buyers should live to figure out when to purchase things. That way they dont need to do any calculations by hand.

My problem is that it shows the Order By date as today even though we don’t drop below min on hand until December. Is there any way to get the order by date to match with the date that I go below min?

MRP & PO Suggestions in Kinetic work differently then some systems… if you have a MIN Qty, the system is predictive and trys to never fall below that minimum. This means that the system does NOT treat this as a “reorder point” but a true minimum.

I just created a new IDEA that would support additional logic supporting a true reorder point in MRP. You can vote for this now: Epicor Ideas: KIN-i-4138 - Add a feature to MRP to allow true REORDER POINT processing for parts

I thought that this may be what you had referred to at the user group meeting. I have already placed my vote. Thanks for answering and creating the Idea.