On one of our PO we ordered 2,000. When it came in, we went in to Receipt entry and, under Mass Receipts, had to change the qty to 2138. It says No record found. Played around a bit and noticed that it only did that when the qty was larger than the ordered amount. Why is it doing this? Should be able to receive more as this happens quite often with the products we order.

Mass Receipt is best for when the entire PO is received, with the exacts amounts. It makes lots of assumptions - like the Qty ordered is what was received. And manually changing the Qty Rcv’d kind of goes against the idea of the “Mass Receipt”.

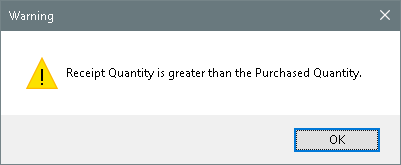

That’s why in Mass Receipt, if you change the Qty to more than the PO, you get the warning:

After clearing the warning, the pressing “Process” again allows it to go through.

Or were you referring to the original Mass Receipt being done with the Rcpt Qty equal to the PO qty, and now you need to go back in and edit the receipt qty to show the Qty actually received?

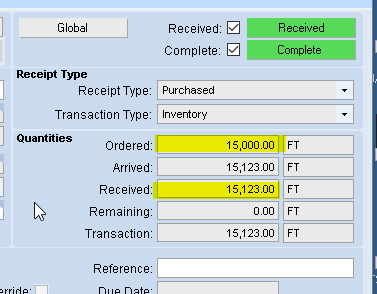

You were right the first time. However, if in Mass Receipt you click Get All first, then type in the amount received, it changes the Qty without an error message. Kinda weird. Before we could click Get All, and I think it was Receive all and still change the qty without any warning or error.

They base everything on assuming you receive what you order or less but not more. This presents itself in EMW and HH module https://epicor-manufacturing.ideas.aha.io/ideas/ERP-I-227. We get double hit ordering lots that almost invariable come in at more than what we order because… well frankly it’s to the vendors advantage and we can’t do anything about it.

I get the pop-up message the instant I leave the Our Qty field in the lower pane of the Mass Rcpt’s window.

Try the Select All first, maybe I was wrong about which button to hit first. All I know is I played with it and got it to work like I had stated.

It’s not uncommon for some of our suppliers to require us to receive up to 5% above the purchase qty, when its something that might have some “shakeout” in production. Sheet metal parts are a good example, as the supplier knows the first couple might not be dialed in exactly right, so instead of under shipping they build their job to make “a couple extra”, so if they have a higher fallout, they can still provide us with the qty ordered.

In reality, they know exactly what they are doing, so we almost always rcv 105 pc’s against an order for 100.

YUP LOL! Worse yet we order in LBs for sheet goods not linear ft or sqft when our bags are yielded in dimensions. #ThicknessMatters

By default Epicor allows over receipt more than the PO quantity, which might be applicable for some parts.

Workaround is to

- create a Over receipt tolerance field in the company master.

- Configure BPM to cross check the overall received quantity with the tolerance limit.

I would be very interested in learning more about the over tolerance field. Could you enlighten me more?

A Custom UD field added in the company master.

This will store the over receipt tolerance.

A BPM which aggregates total received quantity till date and the quantity entered in the current packing slip. Calculate the percentage difference of the Order quantity and the aggregated value compare it with the Over receipt tolerance, if it is more, then restrict the entry.

I’m coming at this issue from the other end. I’m failing an audit control because E10 is allowing me to receive more than ordered, or more specifically, I can can process receipts against closed POs. I do get a warning that says the PO is closed do I want to continue, and another warning saying I’m receive more than ordered, but as long as I hit OK, it still allows me to do it. Is there a setting somewhere that can be used to prevent receipts against closed POs and over-receiving?

@Vlad The system won’t stop an overage only warn. In our business it is common to have overages as the supplier either uses a counting scale or they spool wire or cable up to 10% over as a norm.

You would have to add a bpm to receiving to stop them. I allow them but require a reason for the overage that the auditors can review.

That makes sense, especially for overages/overship. But we have an audit control that says you can’t receive material against a closed po. I’m assuming I need a bpm to block that as well?

Yes, you would need a BPM for this too. However, you should consider how you would handle it if a supplier does send you product for a PO that was previously closed. If you have a hard stop BPM, would you refuse the shipment? If so, you will probably need to adjust your receiving process so you check for an open PO before accepting shipments.

Yeah, we would have Purchasing reopen the PO, add a line, etc.