We have 2 parts that are identical, so we’d like to use the internal part cross reference, but we need to understand how this actually functions as far as transactions go and inventory as both parts are purchased parts on their respective BOMs. Can someone explain this functionality as the help menu didn’t cover in great detail?

I believe Internal Part Cross Reference is just that… its a way of creating a different “reference” to the same part. For example, I have part Number 018-01234… (we added leading zeros in Epicor so they would sort better in part lists). But, in my legacy system, this part was 18-1234.

So the real part number (in Epicor) is 018-01234… but I could create an Internal Part Cross Reference so if anybody enters 18-1234 on a Sales Order (for example)… the system knows this REALLY means 018-01234.

What you may want to explore is “Alternate Parts”. This is found in Part Entry > Alternates

Unfortunately, I don’t know the FULL ramifications of this yet… but early exploration gave me the below understanding…

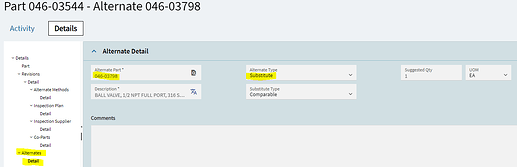

I have Parts 046-03544 & 046-03798… which are the same. In Part Entry of 046-03544, I can add 046-03798 as an Alternate with a “Alternate Type” = Substitute.

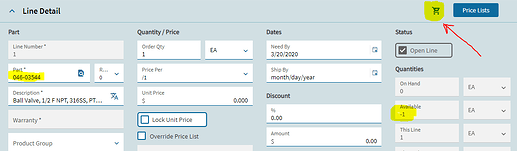

On the Sales Order side… if I SELL 046-03544… I see I have (0) on-hand inventory… BUT, I noticed this little shopping cart icon appeared:

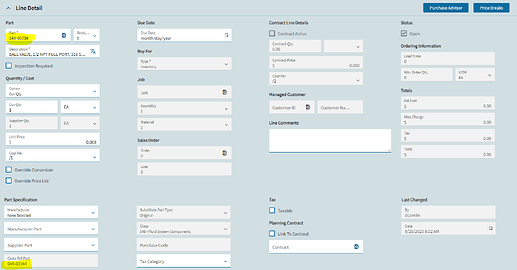

In Classic… it looks like this:

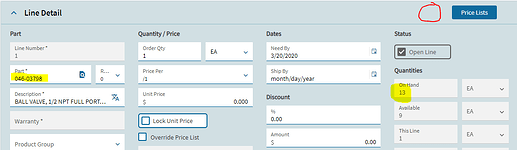

If I click that, I can choose the Alternate Part… and sell that instead. However, it actually changes the Part Number on the Sales Order (which is okay, as long as it doesn’t throw the end customer for a loop that they ordered one thing, but we’re delivering a different part number). But, it does show we have (13) on hand of this “Alternate Part”.

Note in the above image, now that I’m selling 046-03798, that the little icon disappeared. That’s because I only set up this “alternate” relationship one-way. I would need to add 046-03544 as an “alt” under 046-03798 if I wanted to go back the other direction.

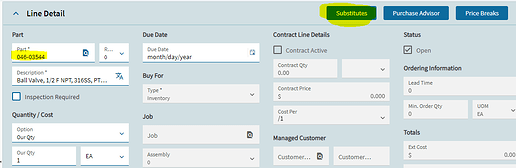

Same thing happens on the PO Entry side. If I try to enter a PO for 046-03544… a new button appears that says there are “Substitutes”:

If I click that and choose the Substitute Part… the PO changes to that alternate part, and will actually show the “Cross Ref Part” that was originally called for on the PO before I switched it:

This is where my “testing” stopped on this functionality. However, I did have some discussions with a consultant. My question was whether “demand” for one part would impact the other in any way. And the answer was “No”. PO Suggestions (etc.) are still going to be driven by the original demand. So if a sales order, etc. is entered for the original part… a PO Suggestion would be created for that original part. It will not take into account that we have inventory on-hand of the “alternate/substitute” part. (I’m sure a customized alert could be set up to flag that inventory exists of a “substitute part”… but I haven’t gone down that path yet).

But… for now, if the Sales Order was for part A, we will get a PO Suggestion for part A… it will not look at Part B automatically. So, I don’t think these “alternates” play into MRP or PO Suggestions.

Interestingly though, from an Engineering point of view, when you set up Alternates, the UOM is dictated by the part you’re setting up as an alternate. So you could say: (12) inches of Part A = (1) Each of Part B.

OR… that it takes qty (2) of Part B to equal qty (1) of Part A.

From what I’ve found, “Alternates” are generally talked about from the Sales/Purchasing side of things. I don’t know if BOMs or Jobs are impacted in any way (doubtful)… they’re going to follow whatever is on their methods.

If you’re looking to “clean things up”… since these are basically duplicate parts… there is a process called “Mass Part Replace”… where you can replace Part A with Part B in all BOMs… then you could make Part A inactive. But again, I haven’t actually DONE that yet in our system.

That’s great incite on the alternative part. What we are really looking to do is when a part is kanban receipted and component abc is at zero on hand it backflushes part xyz in it’s place. If yoou aren’t familiar with kanban receipting it creates a job, pulls in all respective material (from the method), backflushes the inventory and closes the job all at once. Is there a function in Epicor that will do this?