Our company has two sites (Oconomowoc & PMTC). We are coming across the below issue when using Order Job Wizard. Curious if anyone else has experienced this issue? Is it intentional functionality to allow a revision from a different plant to be loaded into a job using the wizard or is this a bug? I do have a case created with EpicCare as well (CS0001750429).

Part only exists in Plant = PMTC

Revision only exists in Plant = PMTC

Order Entry mistakenly enters the SO Line Release while logged into Plant = Oconomowoc making the release From Site default to Oconomowoc even though the part revision does not exist in Oconomowoc.

Suggestion shows up on the Oconomowoc Planning Workbench since the order release indicates we want to fulfill the demand from Oconomowoc

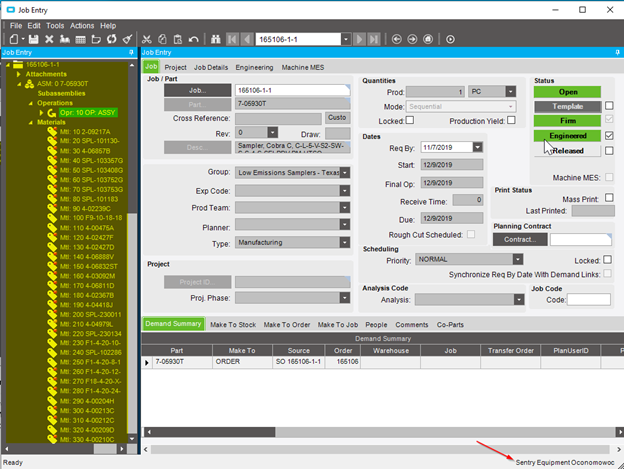

When using the Create Job feature, the Planner selects Order Release and checks the boxes “Get Details” and “Schedule” then Create Job

When Job Entry opens, the job header detail has been created but no BOM/BOO is pulled in because no BOM/BOO exists for this particular part in Plant Oconomowoc. THIS IS CORRECT AND THE EXPECTED BEHAVIOR WE ARE CUSTOM TO. This same behavior occurs if we manually try to create a job in Job Entry for the same part.

However, if we use Order Job Wizard from the planning workbench, the BOM/BOO from Plant PMTC is pulled into the new job even though the BOM/BOO does not exist in Oconomowoc. This is very concerning as how would we know that the BOM/BOO was from a different plant? Why does the Order Job Wizard allow the BOM/BOO from another plant (PMTC) to be pulled into Plant Oconomowoc when the method does not exist in Oconomowoc and the other two methods of job creation (manual and Create Job from PW) don’t allow it?