We carry our parts in 3 to 4 different package types in our warehouse. For example part A may be stocked in a quarter keg that holds 2,500 pieces, a package that hold 100 pieces, another package that holds 50 pieces or in tubs that hold parts waiting to be broken down into packages. How can this be setup so I can track the parts that are being held and sold in these different package modes and also is there a report that will tell me when these different package modes have reached a min quantity and need to be repackaged.

Part Specific UOM is the first place to start. Epicor has the ability to stock in multiple UOMs as well as have different UPC, etc per UOM.

Does E10 have the ability to limit the UOM used by specific bins? I think he’d need that, so he knows he has:

2 KEGS in Bin 1

10 PKS in Bin 2

and 3214 PC in Bin3

instead of it just showing up as a total QOH of 8,214 PC

Bin 1 - 5,000 PC + Bin 2 - 1,000 PC + Bin 2 - 3,214 PC

Thanks, I will start playing around with that first and see if I can make it work

I am carrying these parts in the warehouse on shelves waiting to be sold. So I need to be able to do a couple of things, A. I need to be able to track how many pieces I have on hand in each different package mode and I also need to be able to set min quantity on each package mode so I can initiate an internal order to repackage stock into the various packages as its depleted. Does Epicor have this capability?

As per how the system is designed… Inventory cannot be kept by packages… it is only kept as units.

As per previous posts, I think your issue could be resolved if you name your part with an extra info about package…so your best bet might be to have a different part, per package type. This will garantee min/max and inventory follow-up ?

I do not like it because you loose your part history…unless you can combine by changing the reports…

Pierre

Thanks

as @Jason_Woods said, we can track multiple UOMs… but that only gets you so far… if you turn on the tracking, then it knows how many of each UOM you have, but it will not make recommendations for mins of each one. Just not going to happen with the way the software is designed. MRP does recommendations based on total quantity (in BASE UOM) that you have in the SITE (Plant) and if you have enough, then it will not suggest to make more, even if all the inventory is in one specific UOM that you don’t need.

Another “Trick” would be to create multiple Part Numbers (I know… breaks other rules)… one for each UOM

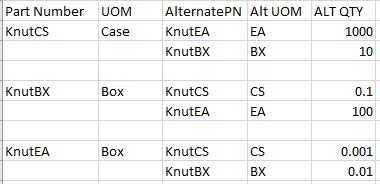

BUT at this point, you can also use the ALTERNATE part numbers to get you back to other UOMs… Since they are different part numbers, each can have their own min/max

For example:

When you define ALTERNATES, and then use one of the parts in a SALES ORDER, it will suggest the alternate (when you press the little alternate button on the sales order entry.

BUT this would only really work if using on the SALES end of things. if you consume the UOMs in JOBS, then you would not get the recommended alternates

On more Idea… You could setup different BINs (or Warehouses) for each UOM… use the KANBAN qty as the quantity that is inside the case… and do some magic within BPMs and Dashboards to show how many Cases you have (vs Eaches)… This would take some customization but it all depends on how structured your warehouse/bin situation is.

Another idea would be to make the base part UOM as PC, and make 2 other part numbers as Sales kits with their own UOM. It wouldn’t solve your problem of knowing how many of each package type you have, but the part trans actually flow through to the base part.

If the packaging (keg, etc.) are inventory items then having separate part numbers with a bill that include the number of parts and the packaging. You get your min/max, and get the order history of these different SKUs. Win-win.

Mark W.

Thanks, I think the idea of keeping separate part numbers will work best. Now when I need to transfer parts from the unpacked container, to one of the separate part number that is a package on the shelf, how is this done?

That would be a job.

It would be a good candidate for Kanban job too.