(Version 10.1.600.5)

My Shipping Manager came to me saying he was using the Fulfillment Workbench to Allocate a Sales Order. His shippers picked the allocation into a Pack, then Staged the Pack to be shipped later. He noticed the next day that the Fulfillment Workbench was telling him that one of the Parts listed in the Sales Order needed to be allocated again, for the same amount, and it caught his attention.

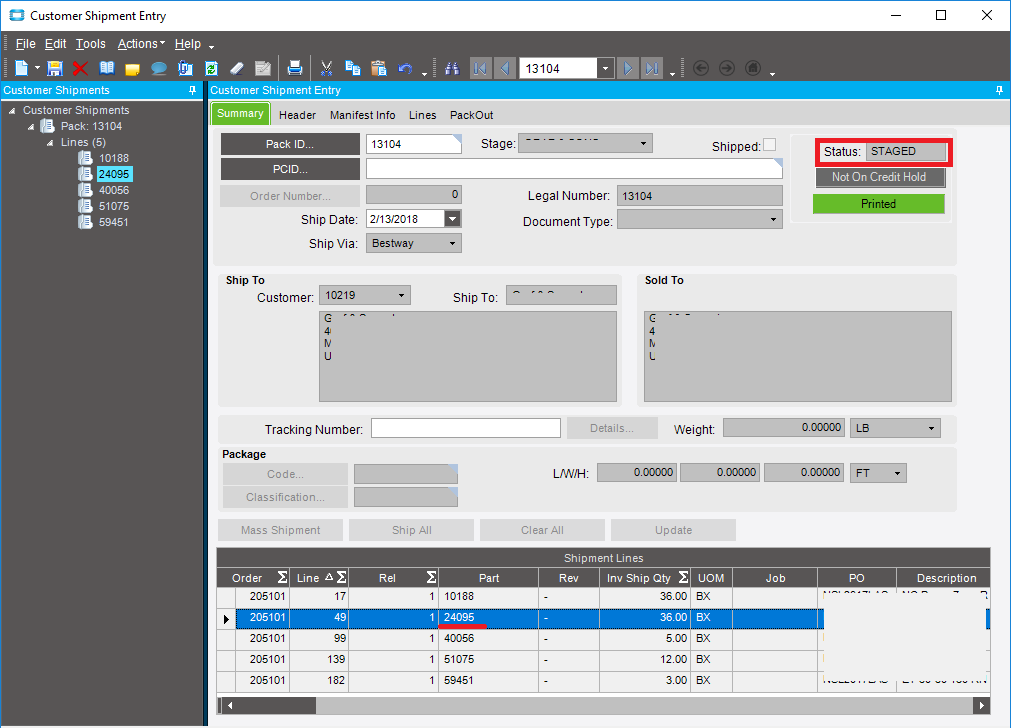

I looked at the Pack in Customer Shipment Entry and verified the part in question (24095 in the image below) was present and that the Pack was marked STAGED:

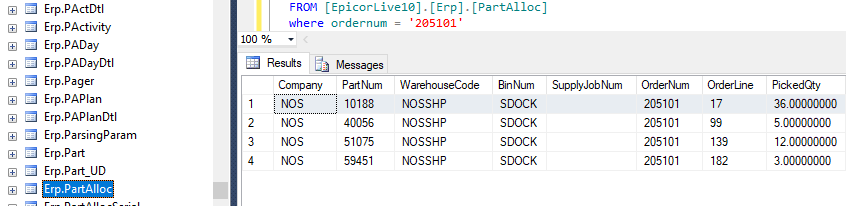

Then I went to SSMS and ran a query on the PartAlloc table for the Sales Order in question and I found something rather odd:

All of the Lines from the Pack were in the PartAlloc table with the correct quantity listed as “PickedQty” as I would expect–EXCEPT this one Part (24095). I asked the Shipping Manager about this Part, and he said it has happened with this same Part a few times in other Allocations, which is why he was bringing it to me.

I queried the Database for this Part along with one of the other Parts that were working properly. I compared them side by side (so far) in the Part and PartPlant tables, and they’re identical (minus Part Class/Product Group). Before I keep going through every table that starts with Part, I thought I’d see if anyone could offer any insight.

Where would you start approaching this to try and get to the root of a Part that’s not Allocating properly? Is there any auditing approach I could take that would help me see if the Shipping Manager truly allocated this properly (I won’t rule user error out), etc? Any thoughts or ideas are very much welcomed, thanks!