We setup a test with an assembly part with sub-assemblies ( production sub-assemblies ) with Plan-as-Assembly in the BOM. According to the MRP-technical-reference MRP should create a subassembly job as Make To Job ( if not enough stock quantity is available and within the cum. leadtime )

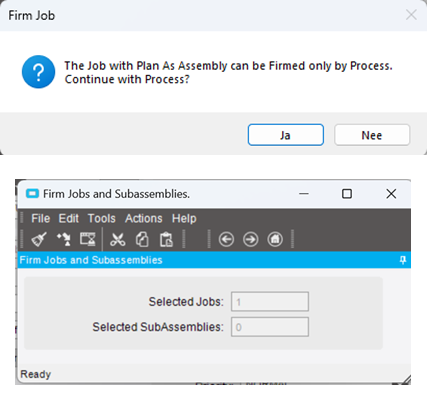

What we see is that MRP creates a job with the Plan-as-Assembly sub-assy pulled in and when firming the job ( manually from Job Entry) we receive the notification “The job with Plan as Assembly can be Firmed only by Process. Continue with Process ?”.

We executed this proces and get a separate job for de sub-assembly, but as Make To Stock and NOT Make To Job ( related to the original job/part ).

Of course, when setting the sub-assembly part as non-stock we will get a Make-To Job / Direct. But that’s not what we (always ) want for this sub-assembly part.

Can anyone inform us how to get the firm job of the sub-assembly (with Plan-as-Assembly ) created with demand link Make-To-Job ?

From MRP technical reference :

Plan As Assembly

Run the Plan As Assembly calculation when you want to automatically generate firm jobs for materials within a method of manufacturing. You activate this functionality within the Engineering Workbench, as you can select this option on a material node within the bill of materials.

When a Plan As Assembly material is evaluated through MRP processing, the MRP engine checks to see if enough on-hand quantity is available within inventory to satisfy this demand material requirement. If enough quantity is available either through current stock or estimated future stock, the material quantity is considered satisfied and it is turned into a material requirement. If not enough quantity is available however, the MRP engine then splits off a new unfirm job for the subassembly that contains this material. This new job contains a Make to Job demand link for the original job record, and the subassembly node within the original job record is automatically changed into a material node.