Good morning, we have been Epicor users since 2014, but are now researching what it would take to move from infinite to finite scheduling. We are a high mix/low volume manufacturing shop. We pride ourselves on delivery and we have many “drop-in” orders that make it difficult to plan demand. I am wondering if there are any companies that are scheduling finite in this kind of environment, and how you deal with the volatility when planning capacity.

We schedule with a finite window of 30 days. Unfortunately, when jobs get released, we are usually just within (or sometimes under) our shop lead time (our material receipts are variable, to put it mildly).

We will schedule infinitely when needed, but also evaluate that decision daily through a scheduling review of released jobs. If jobs can’t meet target date, scheduling works with planning to see what changes can be made.

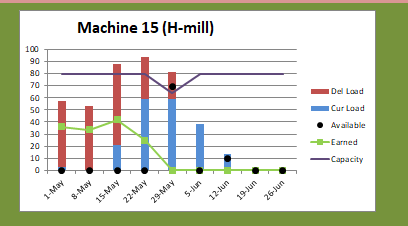

To address the increased load that infinite scheduling of certain jobs can create, we have a visual load report that we populate from the Shop Load Report.

Thanks for your reply! What is your typical lead time on your product? Do you feed updated lead time to your customer service in any way, or do they just work off a standard lead time?

We’re in a bit of an unusual place here, we’re reaching for the stars. Our plan here is to drive all procurement through Epicor to transition out of some bad habits.

The main issue that we have with finite scheduling is that jobs that are scheduled infinitely have shorter lead times than jobs that are scheduled finitely. This makes sense, as the finitely scheduled jobs should take longer, as they have to contend with other released jobs for the same equipment.

In order to create consistent lead times throughout a plan (which for us can be 2-4 years in length), we are gradually increasing queue times so the infinite jobs and the finite jobs have roughly the same lead time.

The final challenge is that when we are scheduling finite jobs, Epicor does not “ignore” queue times, which is contrary to the product documentation. Makes a lot more manual scheduling for me. Still investigating this, as I am not sure if the finitely scheduled job just “displays” queue time in job scheduling board, or actually uses it.

Product lead times here are a mix of short cycle material (less than a week, no procurement needed) and long term (12-26 weeks cycle time with procurement lead times that can exceed a year).