Hi Friends. I am working with Honeywell CT45XP handhelds at our company, and we have been using them for a little over a year. I have just put together a customized Datamatrix code that combines the part number, the from warehouse, and the quantity (hard coded to 1 ea.) in a single label so that the pickers can have the information defaulted when they go to pick and a part on the Move Inventory screen. I put the code into the scanner settings on live and on test in 2 different handhelds. The handheld running in my test environment is reading the barcode correctly and inputting the correct part number, quantity of 1, and from warehouse. The handheld running on live has the exact same code (copy and pasted) in the scanner settings and is reading the barcode with the correct fields, except that instead of putting 1 in the quantity field, it is reverting back to the entire quantity that is in the primary bin of the selected warehouse.

Has anyone run into this issue? I have verified that all of the other settings match between handhelds and we recently flashed over a copy of live into test and all of the setting would have carried over then too. I verified that the code in the scanner settings page matches. I have reordered the variables to see if processing quantity last would do anything.

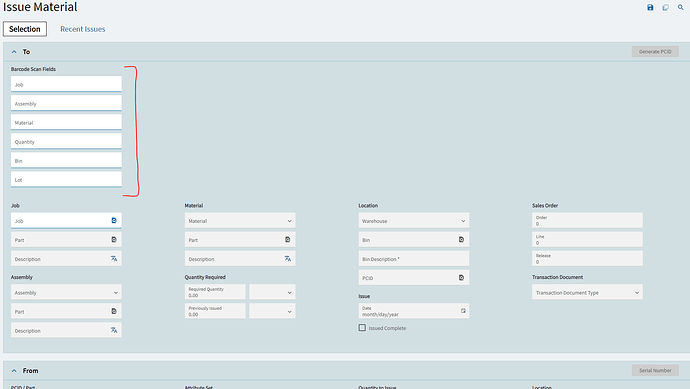

I have noticed that it attempts to put my scanned quantity in the quantity field for a split second and then the app decides to revert it back to the total quantity in the bin. Is there a “pause” that I could code into the barcode to allow epicor to do its weird autopopulate function and then override it with my quantity?