Most if not all of our SOs will require make direct due to an in house certification system that requires customer information and that will work well for us. The problem arises once we finish the job. Currently the product will sit on the shelf and wait for it to be requested by the customer it was made for. Upper management wants to be able to see Finished Goods inventory which you wouldn’t be able to see if it is still sitting in the job. Are there any repercussions if we do a Job Receipt to Inventory and close the job, so that way we are shipping from inventory. Or is there another option for this type of situation?

The biggest pain will be creating a new Partnum every time. As you cannot put it into inventory unless a P/N exists and it is setup as Qty Bearing.

Does management want to to see the dollars in FG, or that actual FG product on hand?

If the job is set as make direct and while you can do a job receipt and probably even ship from stock if you don’t ship from the job it will not close. You would make the job make to stock and the sales order will ship from stock.

I always tell our people you have to tell Epicor what you are going to do and then do exactly what you told it or Epicor will make you pay.

we get around this by having a soft link that I manage to connect the sales order to the job even though it is shipping from stock.

What if the job is closed manually after the job receipt to inventory?

The soft link that you mentioned is that done by a BPM and user defined tables/fields? Does it work with MRP or manually created jobs?

Unfortunately I am not sure which one they want. That is something that has to be discussed.

Really push the part about having to create a part entry in the system, if the want to have it appear as finished goods inventory.

We primarily make to order, but have a couple configurations of our product that we can make and stock. But since we often need to ship the product to another plant, the only way to do that transfer is from plant A’s inventory to Plant B’s inventory. There for the item needs a part entry.

We typically have 600-700 different parts on hand, but have over 3000 part numbers. The bulk of those are used exactly once.

Ask management if you need to generate count tickets for all part numbers? And how gets to look for those 2,300 parts that are active, but have zero QOH.

And depending on your costing method, the part numbers will have to be unique, to avoid mixing the costs of different assemblies.

I calculate it by doing a timephase calculation when they run their schedule.

I think it is a problem with the wip capture process that made accounting come with pitchforks when they would do this.

Calvin,

What would be the answer to the first part of your question, if management wants to see the dollars in FG? I have a similar situation, that I feel is more $ related not parts in inventory related.

We have many configurable, make direct sales orders that sit in “WIP” for long periods of time and they don’t view them as FG at that point but would like it.

To answer your question with another question … Do they need it to be in a different GL acct, or would a report of the $ in WIP that are of “finished goods” suffice?

If it is the later, you could make a BAQ report to determine the value in WIP that is really FG.

If making BAQ Reports isn’t your thing, you could run the WIP Recon report, filtering by Jobs that you know are completed, and haven’t shipped yet. Actually, if they have shipped that would be okay, as the MFG-CUS transaction would subtract out those costs.

Edit:

That would actually give you the costs, based on materials, and would exclude labor.

The jobs will close if there is no WIP on it. We do the same thing with jobs that are make to order since they do not ship right away. So all our jobs are received into inventory and then shipped from there. This gives visibility to stock in hand. We do not use MRP so do not know what impact it will have on it.

Thanks

Vinay Kamboj

We deal with this issue by putting user defined fields for the Sales Order, Line and Release on the Make to Stock tab in the job. We need customer order information on our carton labels at the time of manufacturing such as customer PO number, customer name and ship to address.

The fields work well as long as someone remembers to populate them correctly (customer service reps do this when they create the jobs). There are a few issues such as if the order is to be split to send to two different ship To addresses, etc., so we have manual work arounds for those issues.

Beth,

The fields work well as long as someone remembers to populate them correctly (customer service reps do this when they create the jobs). There are a few issues such as if the order is to be split to send to two different ship To

addresses, etc., so we have manual work arounds for those issues. <<

The different ship-to should be different releases, so the best thing to do would be to make multiple stock demands and that way you can keep the release information. This is assuming the split is known up front. If after the fact, I would

think you are updating the order (for shipping purposes) you would then modify the original demand and create the second demand to maintain the production qty.

Charlie

I mentioned this to my supervisor and he told me he actually did this in the very beginning (we are still implementing) and then he moved away from make to stock so it was pushed off to the side. This would definitely be something that we would want to try and test because in our current system jobs are manually linked to SO, SO line and SO release.

I haven’t been able to create more than one make to stock demand on a job. It allows me to create a make to stock demand and a make to job demand on the same job but not two make to stock demands on the same job. Is there a trick to it that I’m missing?

The only downside to it is that after creating the order and the job, then the person must remember to add the Sales Order to the demand link. Every once in awhile, I run across one where someone forgot to add it.

I would say for us the saving grace is that our certification for the product and labels depending on customer won’t print correctly. In which case we could write a BPM or BAQ for jobs that don’t have that link and put it on the customer service home page. As far as I know we are going to use a specific part class for finished goods which should allow me to filter the query.

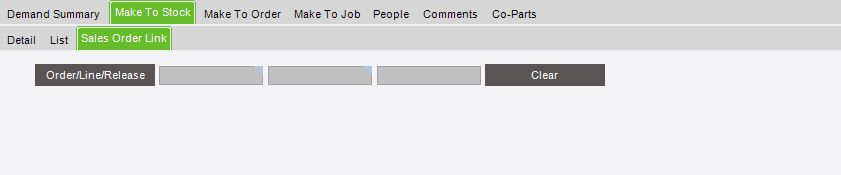

To give everyone an update here is what I did. I added a Sales Order Link tab to the Make to Stock tab. I made it so the Order, Line, Release text boxes are always read-only to force the user to perform an order, line, and release search. I used the UD Column Maintenance form to create a table based on JobHead and stored the 3 values there. For the possible issue of a user forgetting to assign an Order/Line/Release to a Make to Stock job I have created a BAQ that displays jobs that do not have a link based on Open Order parts.

I haven’t been able to create more than one make to stock demand on a job.

Make to Stock links seem constrained to unique warehouses.

That explains it and makes sense. We have one stock warehouse.