Is anyone in here have experience with a CMMS like Maximo and utilized Epicor in a similar fashion. I recently took over as maintenance manager at a facility using Epicor and I dont know what I dont know about it and have found little training documentation online. I am use to being able to attach parts easily to work orders. Also is there a more streamline way for mechanics to account for there time. Having to add operations line is very clunky to me. compared to previous CMMS systems I have used. They have been only been completing job for the past few years here but not accounting for hours. Any help or guidance would be greatly appreciated

IMHO, the Epicor maintenance module is a joke. We ditched it altogether and switched to a separate CMMS (UpKeep). Are you stuck with using Epicor, or do you have the option to switch to a different system?

Unfortunately, what you are seeing is how it works. There really isn’t a great way to streamline the process of making the maintenance job and managing it.

For logging time to the jobs, I would take a look at Office MES. It’s a simplified version of the production MES that allows you to clock into an operation on a job and then clock out when you stop or complete it. As long as the right job is selected, the time is logged by the user and to the operation(s) that they clock in to.

Additionally, if you have access to BAQ or have an IT team that can for you, it would be easy enough to create an updateable dashboard that would allow you to monitor the job status and log time, etc. to an operation on the maintenance job.

We have found that using Templates which can be assigned to the Company as a whole, to each Site/Plant, and to specific Equipment IDs has helped reduce some of the overhead related to adding operations to jobs. Adding these templates will automatically copy the template operations and materials to jobs created from maintenance requests. You can also copy a template to a manually created job.

I agree with using Office MES or the actual MES program on the production floor - mechanics can clock into their maintenance jobs just like production operators clock into production jobs and it will track “real” time.

I see that you’re using templates successfully. My engineering team have a few plans with a template attached. We’re not seeing them get carried over to the instance job. Specifically, the Job Description ends up being the Equip Plan description, and NOT the description from the job itself.

Are you aware of a config setting to control this? Is this how you see your system behave?

Thanks!

Mark

Yes, that’s how it’s working for us. I don’t think there is a setting to change this, and we actually do want the equipment plan’s description to overwrite the template’s description when each instance of the job is created.

Can you make the description on the equipment plan match the template’s description?

Ah thanks for replying - I know it was an old thread…!

They want the Maintenance Plan Desc to be something like “Annual Valve Service”, but on the template job it would be far more detailed as to the steps required to undertake said service.

Cheers.

The way we would set this up would be:

- Equipment Plan Description: “Annual Valve Service”

- Template Job Description: “Annual Valve Service Template” (or something else that means something to your team)

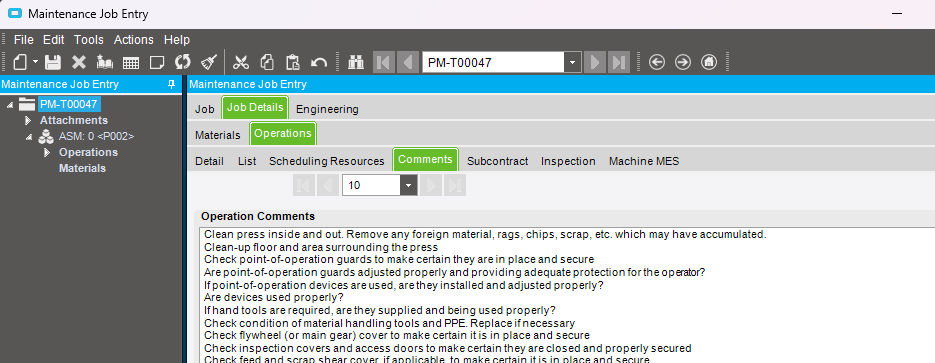

- Template Job Operation Comments: This is where you put the step-by-step instructions for performing the service

The Operation Comments are not overwritten when the template job is created and are copied to the instance job faithfully, so that is where any job-specific detail should be entered that you want to appear on both the template and the job.

As an example:

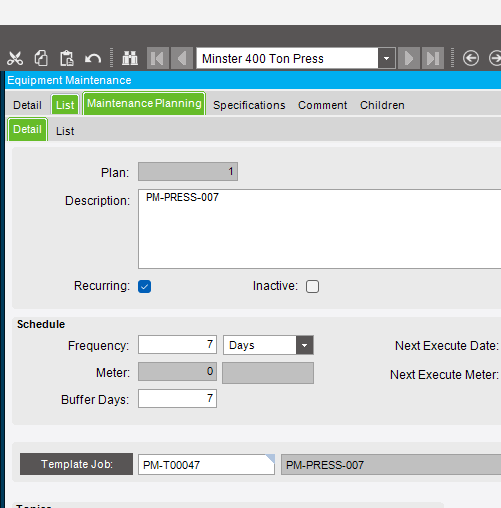

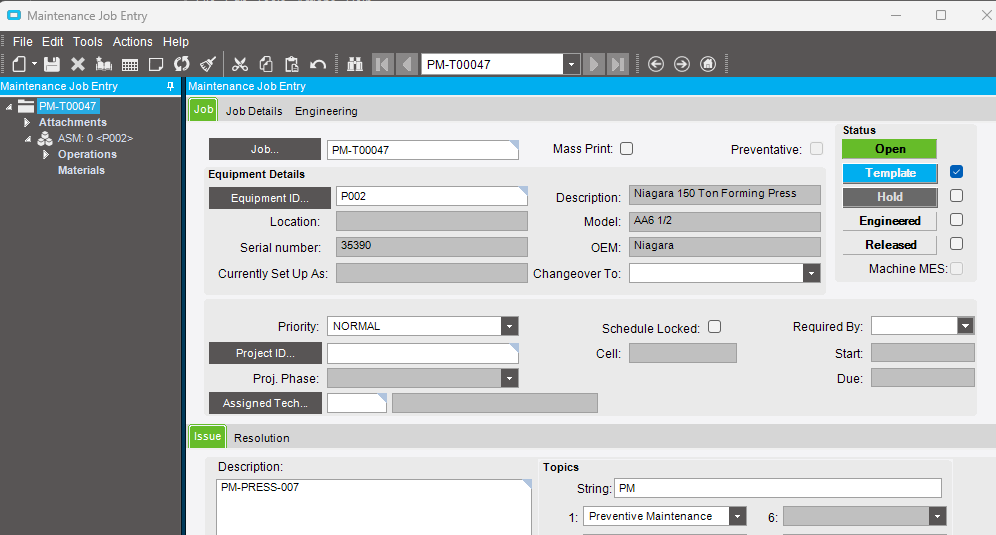

One of our 400 ton presses has a monthly check called “PM-PRESS-007” (our team likes to use codes for descriptions…)

The template job attached to this plan has the same description under Issue Description. Notice that it’s not detailed at all:

Then under the PM operation, we have entered the specific comments about what to actually do:

Thanks so much for the detailed reply, great assistance.