I have an order, and for ease of shop pass-thru it is 30 individual jobs tied to individual releases on a sales order.

We desire to purchase the material to manufacture these parts on a 31st job since it requires some outside vendor work before we can begin. Essentially bringing it in semi-finished, with a material link to each job. This also allows us to order extra material, but have the cost divide by the total number of production parts.

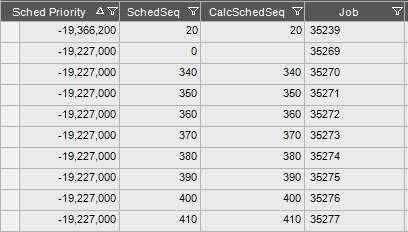

However, when I run my schedule, it seems in a correct position, but I don’t get a Schedule Sequence number from “Calc Global Scheduling Order”. This job will be at the front of the line due to it’s priority, but only the first job tied from the subjob seems to produce a schedule sequence order. If I dig deeper into the behind the scenes, all of the jobs hold the same “SchedPriorirty” (the value generated by the Calc Global Scheduling Order run above), however it doesn’t get assigned a schedule sequence.

(for reference, CalcSchedSeq is the normal field we use… it will pull the schedseq value from the top line sales order job if it is a child job, these are all direct order jobs, so they match)

Sure, I can manually add it every time I do a schedule run, but that’ll be hundreds (if not thousands) of times before these parts are completed. We use the schedule sequence number to visually identify priority between two jobs for team members on the floor… so having NOTHING there is a no/go, especially on something thats a top priority…

Any one else notice this or have a fix/workaround?

Thanks!