Would someone please explain, step by step, the proper method for processing a job from start to finish? Let’s simplify things by limiting the scope to a job to make a gizmo for stock.

This would be if you are creating the job manually, and you already have a part with an approved revision (meaning I’m blithely ignoring MRP and the entire Planning function)

- Job Entry - create a new job

- Enter the Part Number (the most recent approved Revision will autopopulate)

- enter a Due Date

- create a new Demand Link for Make to Stock, enter your production quantity

- Get Details to populate the MOM

- select the Engineered checkbox (enter audit comments if prompted)

- Schedule the job

- Release the job (enter audit comments if prompted)

- Issue materials

- enter labor

WHEN PRODUCTION IS COMPLETE: - open Job Closing

- check to make sure your materials and labor are within your tolerances

- mark the job COMPLETE.

- exit Job Closing

- open Job Receipt to Inventory

- receive your completed quantity into inventory

That is the production/operations side of the job process. Typically after this point Finance takes over and, after checking that all the Finance stuff is done, closes the job.

I’ve skipped and/or glossed over a LOT of things, but that is the skeleton.

If you can be more specific about what you are trying to understand, we can get more detailed.

Thank you Ernie. This may have seemed like a stupid question, but I am after all, a “Rookie” when it comes to Epicor.

This is where I was tripped up. When processing a part as a Kanban Receipt, the material was processed through to inventory as one would expect. When processing a job as above, they were not. I never would have imagined that one would have to issue the material of a job completion to inventory in a separate process. Why is it that, when Epicor defines job quantities as Made to Stock (inventory), Made to Order, and Made to Job (sub-job), that one must manually issue the material to inventory (Job Receipt to Inventory), or another job (Job Receipt to Job). (It appears that it is not necessary to manually issue a job to an order as I haven’t discovered a companion form.)

This is not a rhetorical question. I really want to know why.

Great question.

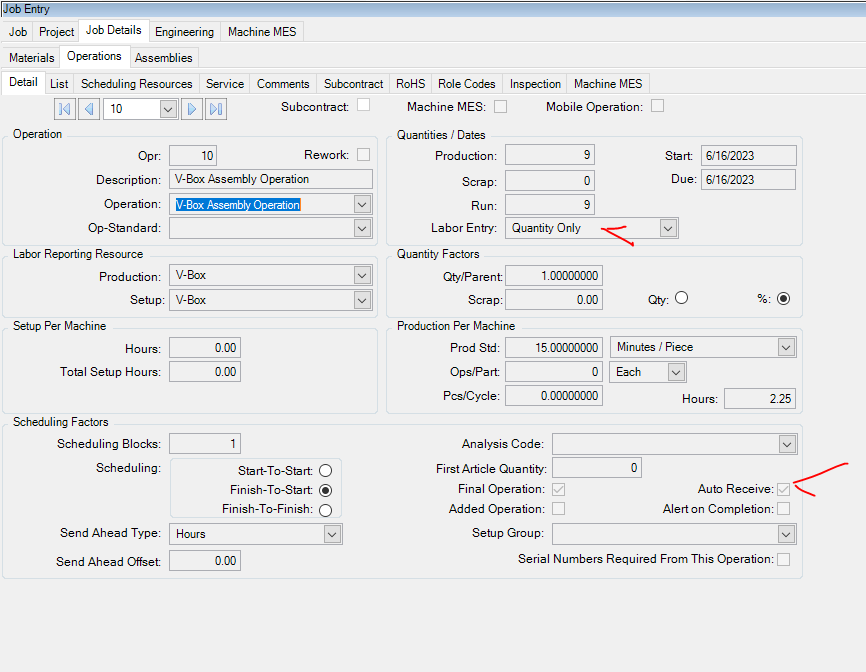

Kanban Receipts is designed to be a very quick and unintrusive process. It automates a LOT of parts. Typical Job processing gives you all the bells and whistles, and lets you decide what you need to automate. There is a checkbox on the Scheduling Factors card (in Kinetic) labeled “Auto Receive”, when this is selected on the final operation quantities completed through that operation are automatically transacted into their default inventory location at their default cost method (both from the Part settings).

Hi Tom

One thing you can do to help automate the Receipt to Inventory is have your last operation flagged as Auto Receive . This will receive the inventory into stock as you record the Labor to the last operation ( assuming the operation is anything but backflush). Where it receives to Inventory ( bin ) is another story, depends on set up…

Dean

@Rookie A lot of the premises in Epicor IMO are built around a very large plant or a campus.

Incoming receipts can be arrived, but not received. Jobs can be finished, but not actually in inventory yet since they are in a move queue going to be put into a warehouse two doors down.

As @DeanMiller points out you can automate this with auto receive, but that does take out a layer of accountability that the material was actually put into inventory.

Make Direct for a sales order ships from the job and does not do an inventory transaction.