Our sales orders are entered as Make Direct. Jobs are made from those orders. We then Receive to Inventory to record the production quantities and lot numbers (as opposed to waiting to assign lots at time of shipment). When we go to ship, we enter the SO and the Job into the Customer Shipment. But, the shipment still requires us to select lots from everything in inventory. Is there some way to have the shipment pull the lots and quantities that were Received to Inventory from the Job?

Develop a BPM on Erp.CustShip.GetOrderRelInfo Post-Processing to get qty and lot number from PartTran.

Help me understand why you are receiving a Make Direct job to Inventory. Is it to print a lot number on the label? Is your job number your lot number?

Yes, we are receiving to inventory in order to print the lot number on the box and to include the shift in the lot number.

When you bring MTO to inventory two things can happen to watch out for. If you close the job MRP, if you are using MRP, will trip off new supply requirements. The second issue is you will lose P&L in production detail because it no longer makes the job/order association.

Only mentioning in case this is a new process.

@ jgiese.wci Thanks for the comments. Those are extremely important points, which we were unaware of. This is a new process for us. We may have to rethink the Receipt to Inventory process.

What is the business case for not having the Order be Ship from Invntory, with the Job setup as make to inventory? Is it just to keep the JobNum as “Order-Line-Rel” ??

@ckrusen, some of our business is truly make to order with special customer requirements. We make a specific production run to fill those orders.

I wasn’t suggesting making a standing inventory ahead of orders. Just tweaking what you’re doing.

In order to receive it to inventory, you must be creating part numbers. So the only tweaks you need are to change the Order Release to be “No Job”, and select the warehouse they’ll be shipped from. This will create a demand for inventory. You’ll create a Job to fulfill that demand.

Ah, I see what you are saying. But, I think that would put us back to not having P&L for the job since the job would not be tied to the order, correct?

You might lose that immediate connection between the Job and the Order, but if you still make the Job Num the Order-Line-Rel, it would be very easy to re-establish that connection.

And since you’re recieving to Stock, the Cost of the Job is captured at the time of the receipt. And that cost is what is used as the COS when the items ship against an order. One thing that might throw a wrench it to this is the Costing Method used. The type AVG would be “best”, and STD would be the “worst”

I think this is what I was missing …

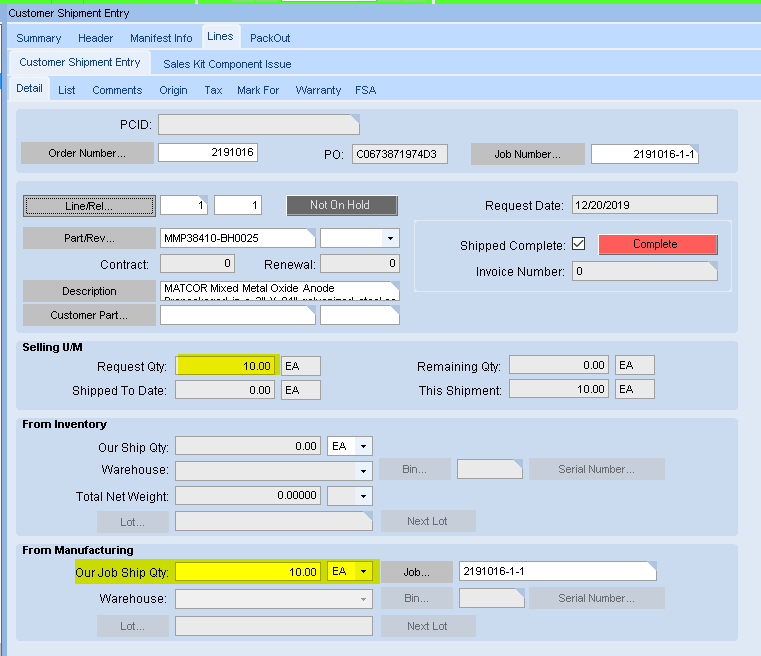

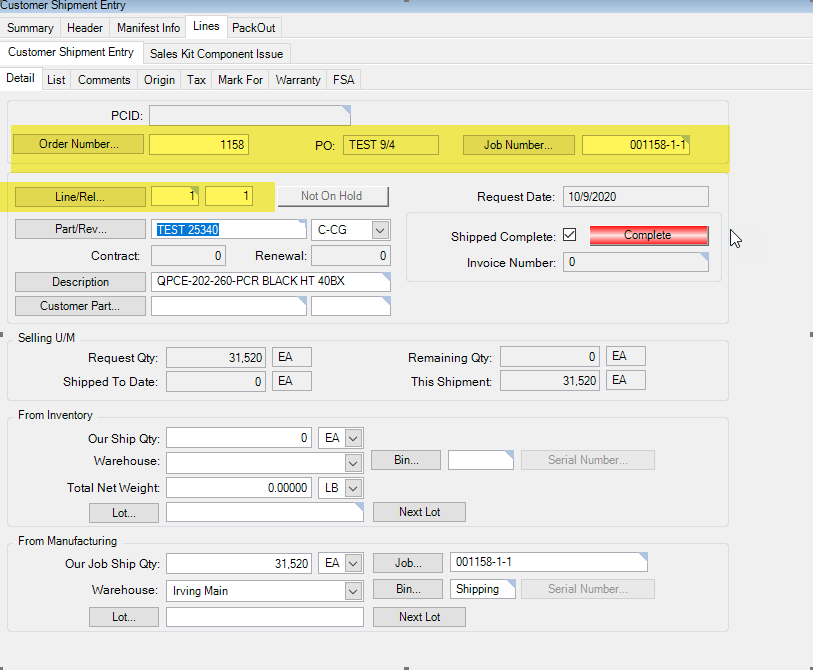

So on Customer Shipment, when you enter the Job Num on a Shipment line, are you entering a qty too?

Or do you enter the Qty in the “From Inventory” field (which requires Bins and Lot Nums), and enter the Job in the “From Job” field, but leave its Qty blank?

We enter the sales order and the job on top portion of the shipment line. Then, we select lots in the From Manufacturing section. This is the part we are wanting to not do, since we assign lots when we Receive to Inventory from the job. But, since Receive to Inventory breaks job P&L and MRP, we might have to rethink that.

When you do that, the Qty to ship is From Job? (Like the following)

With most of the fields in the “From Inventory” and “From Manufacturing” being disabled?

You can also assign the lot numbers during the shipment process… and making a “label” to print said lot number should not be terribly difficult. I might look leaving all your other processes the same as they are, but do not receive to inventory (which appears to be the problem child here).

@Ernie,

Thanks for the reply and suggestion. We manually assign lot numbers for each line and shift and print the lot numbers on box labels. The challenge with assigning lots at time of shipment would be identifying the lot numbers and quantities that are going with the shipment - determining exactly how much of which lots are we shipping.

That helps. So the shipment makes MFG-CUS part transactions? Do you have to manually relieve inventory?

Yes, the shipments make MFG-CUS part transactions. We manually relieve inventory because it is lot tracked.

If you wish to go down the path of Make to Stock from Make Direct based on business needs, you can consider using LOT Costing method (Lot average) using which still you will get correct PL for the order as the cost is tracked by Lot number.