Why are these items shown in the tree twice? Once in the Subassemblies node and again in each assembly’s 1st operation node?

I’m not seeing any value in having them here again… ?

Why are these items shown in the tree twice? Once in the Subassemblies node and again in each assembly’s 1st operation node?

I’m not seeing any value in having them here again… ?

It provides a view of everything required for that specific operation. So you know that Op10 requires these resources and materials/assemblies. It makes it easier to see what is needed for an operation instead of clicking on each material/assembly to see where it is used.

Hmm that was my thought too, thanks.

But it’s only on all 1st operations, and all the assembly and material components are always listed under that 1st operation. And then all subsequent operations never have any listed.

Is that set somewhere? Ie set which specific materials/subassemblies are used by an operation?

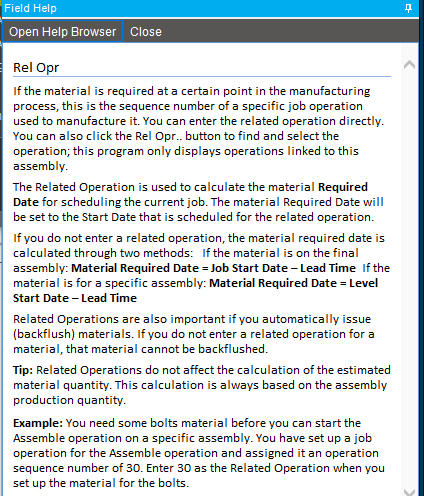

Yes, for materials and assemblies, you determine which operation it is needed at. Most people do not do that and the default is the first operation.

If you tie the material/assembly to the correct operation, PO suggestions will give you better dates.

The Job Entry screen shows the exact same thing too.

Ah this is set on the Material or Subassembly Related Operation field. And if it is set to zero, then it defaults to the first operation. Thanks!

And if you backflush then when the associated operation has completions then the material is issued then.

Followup - For refurb jobs, we have some initial operations on Asm 0 that need to be done before anything else. Eg disassembly, inspection, writeup. If we change the Related Operation on all the subassemblies and materials from 0 to 100, that moves all those materials to eg op 100 in the tree.

So will this cause Scheduling to know to start OpSeq 10, even though all the components are incomplete/unordered yet? Or will scheduling still want all of the components to be complete in order to start Asm 0 Op 10?

The field help doesn’t discuss this. I’m looking for a scheduling guide…

Thanks again.

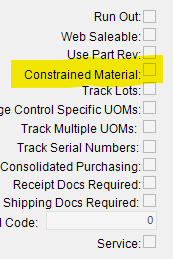

The only way that scheduling will not schedule a job based on the materials is if the materials are marked as Constrained. As long as the parts are not marked as Constrained, you should be fine.

Hmm maybe I didn’t word my question well, or maybe I’m not following your answer… I don’t see a Constrained option on JobMaterial or Part record…?

Say Asm 0 Opr 10 is a typical Assemble operation, requiring all materials and subassemblies to be complete/issued for it to occur (Related Operation). I would expect scheduling to not schedule that operation until after all the materials and subassemblies were available.

But if Opr 10 was a different operation, not requiring materials or subassemblies - I’m looking for confirmation that Scheduling would schedule that operation first thing.

Constrained Material is one of the checkboxes on Part/Detail.

Epicor will only not schedule an operation if there is a material marked as constrained. There is no way to guarantee that the materials and subassemblies will be complete by the time the operation is scheduled to start. What the engine is outputting is the estimated dates based on your MOM. You need to use the provided screens (like Production Planner Workbench) to monitor the variables and manually push schedules out if the parts are not going to be ready in time. Or, you can Globally Reschedule so that if an Opr not completed today is updated overnight to push to Monday. But then you will just be chasing your tail.