Hello all, I would like your insight and opinions on the options.

The Back Story

We have a customer that orders a specialty printed part. We produce the part, and send it out to a third party for printing. We then get that part back and ship it out to the customer.

What they are currently doing in Epicor.

They are taking an order, producing the part, and shipping the part to be printed.

They transfer the material to an outsource warehouse.

When it comes back, they are adjusting out the material, and producing it again under a “Labeling” job, under the same part #.

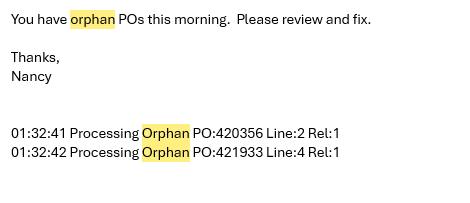

Obviously, this is not desirable, nor sustainable, as the qty of these orders is increasing, and it’s not a one-off anymore.

Options?

I see it as we have two options →

Option 1 →

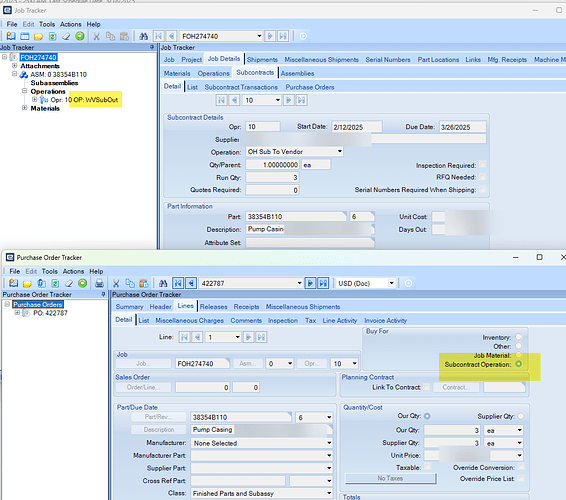

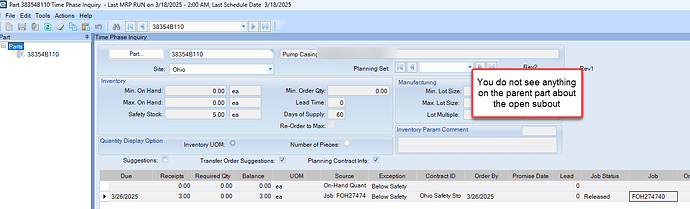

Run all the material as one job, and have a subcontract as an operation on the job for printing.

Only problem is, I don’t know how this works, and what are the pitfalls or things we need to know with this.

Option 2 →

Consume the original part “A” in a job, and create a new part “B” that is shipped to the customer. (I would assume the customer would order “B”.)

Again, the same issues apply, I’m not sure how to track and make all this make sense.

Anyway, if y’all could give me some insight and examples of how you’ve dealt with these issues, I would be eternally grateful.