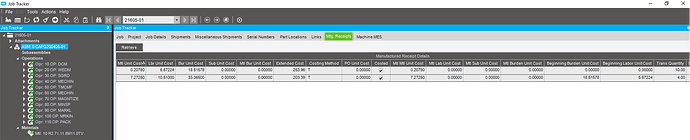

I have noticed that in Job Tracker under MFG receipts as well as in Part Tracker that it seems the unit costs stack on top of each other. Can someone let me know why the beginning prices would start at the previous runs unit price for this job? Its making the 2nd transaction look like its ~$50 per unit instead of the ~$25

Job receipts to inventory use the labor that is already applied to the job to calculate the cost. So if you are receiving inventory before your workers have clocked out of their activities, it doesn’t take into account those transactions. Then after they clock out, that labor cost gets all put into the next parts that get received. If you are running average cost, this ends up not mattering because of the way the inventory cost is calculated (unless you start shipping inventory before you finish the job).

For job costing, do yourself a favor and just look at the overall cost/qty. We’ve researched these numbers a lot and every time someone thinks something is wrong, we can follow through the (complicated) logic and it’s all captured and right. We did make quirky BPM’s with our process to end activity for everyone on the job, report/receive the quantity to inventory, then clock them back in to combat some of this. But that’s extreme and I wouldn’t do that if you don’t have a really compelling reason to do that.

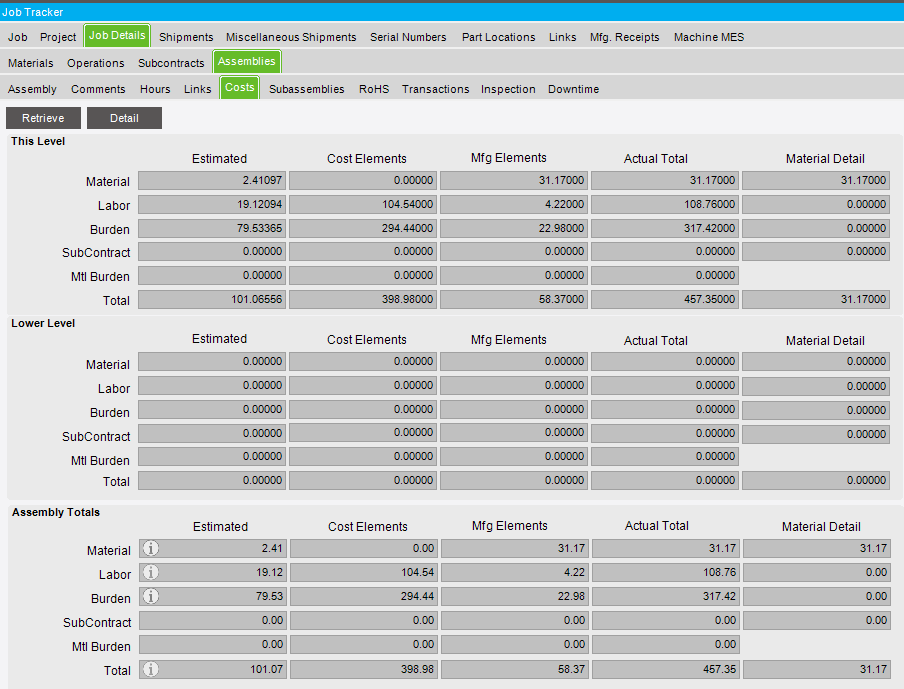

So in this case what you are saying is I should look at the total from the actual total column near the bottom and divide that by the qty?

Yeah. But, with the cost being so high compared to your estimate though, I wonder if you have an outlier labor transaction (did someone forget to clock out?)? Unless your standards are just way off.

Long story short I inherited this system about 2 months ago while no one was officially maintaining anything for 2 years. Some people learned and filled in to keep things going but no one was dedicated to it so either of those options could be true. I will need to look into it more. Just wanted to understand what I was looking at as I hadn’t ever noticed that before.

Welcome to the machine.

Costing is a beast and takes a while to get your head around it.

Can you make BAQs? If you can, look at the laborDtl records for that job. I bet you’ll find one that pops out as way higher than the rest.

Thanks, I was in it for the last few years but was working under some super smart guys who had a bunch of experience. Now I am off on my own without my guardians ![]()

That’s the fun part! Things will start to click since you have already worked under them and now you gotta take what you learned and apply it through a little trial and error ![]()

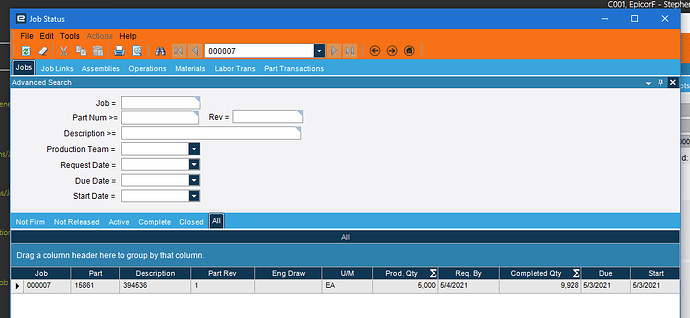

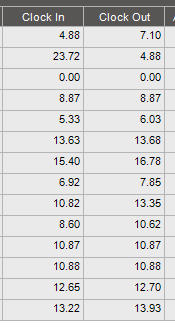

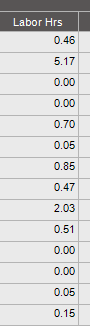

Looks like there are clock ins and outs.

What’s the labor hours on those records? That’s just a time, not a date.

Yeah its been good so far. Lots of big asks coming my way since they haven’t had anyone but I will figure it out one way or another.

@Banderson , @jkane , @Nancy_Hoyt , and @althomas are some names that come to mind when I think of costing. There are many others who are also have a ton of experience.

Without knowing your business, do those numbers seem right? Someone would be doing that for 5 hours, or 2 hours? The rest seem really small compared to those two.

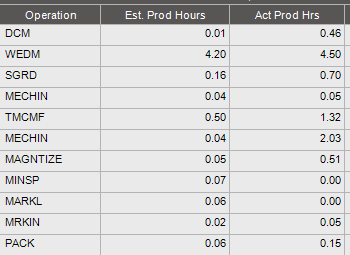

It seems that operation 60 is pretty off in the time it took versus the est. prod hours. Other than that everything is within a much closer margin.

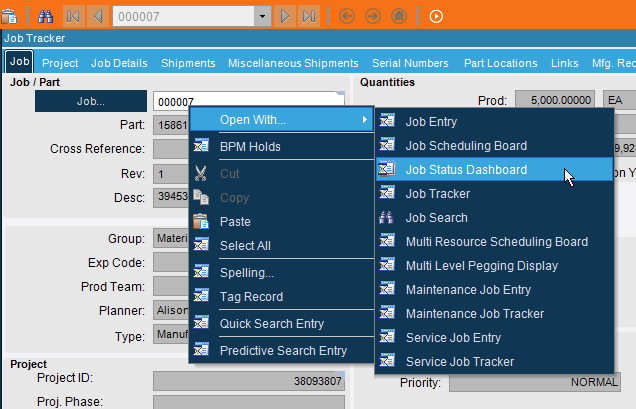

What costing method do you use (Standard, Average, etc ?)

I don’t honestly know the answer to that.

Look in part entry or tracker. Main screen, bottom right corner. Each part can be set to a specific costing method.