Hello All,

This probably doesn’t follow @Banderson 's tips on how to ask a question to this forum but take it for what you will and feel free to answer any of the questions found within this post. I am not looking for a one-size-fits-all answer, but some business examples to get our minds thinking. I will post the question we have, followed by a background of our company, what we have tried so far, and then what some users have started to do as a result of not understanding whether or not the forecast functionality in Epicor will work for us.

Question(s):

In short, what technology are you using to forecast and then buy to forecasts within Epicor? Is it a manual process, fully integrated (forecasts loaded into Epicor and Epicor does the rest), or is it mixed? Have you had success using the forecasting functionality in Epicor with multi-level BOMs?

Background: we are a make to order manufacturer with large-ish, multi-level BOMs containing multiple sub-assemblies- all of which have one or more purchased parts in them.

What we have tried or read about so far:

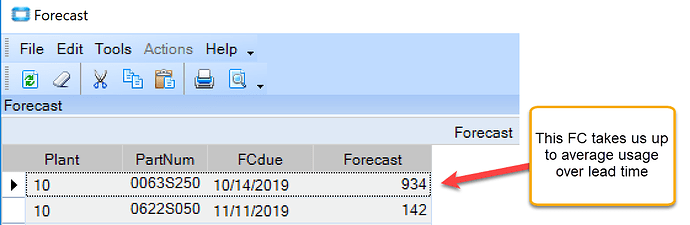

A colleague and I tested forecasting last night by setting one up for a part and then running generate suggestions. It seems alright, but more testing is needed. We saw the forecast in time phase but didn’t see suggestions based on forecast because we had more than enough on hand to cover demand and forecast. I assume that when a forecast exceeds our supply, we will get a suggestion to purchase to the forecast…? We also don’t know if it will work when we only load a forecast for a top level part… will there be a forecast created for lower level purchased part contained in the BOM…? More questions about this, but before we dig into this too much I just wanted to ask if other manufacturers like us have had success using the Epicor forecast functionality

Our Current State:

A large focus has been put on forecasting and purchasing to forecasts and because others tried using this functionality in the past without success (Epicor 9), we are now trying to use external tools (excel) to help us purchase to forecast. As stated, numerous excel sheets are being maintained to help set forecasts and buy to forecasts. One sheet has the top-level parts and their forecasts and then our buyer has a separate list of long lead time child parts that are found in the top-level parts. Our buyer maintains the child part worksheet by looking at time phase for each one of the child parts, updating the demand by week, adding in forecast values, updating the scheduled receipt quantities, checking MOH values, and lastly, manually creating any POs to cover gaps between supply and demand.

We see some opportunities to take out wasted time, but also to ask this lovely group how they are operating because this seems like a lot of manual work with standalone data silos in different departments -something that an ERP system is supposed to alleviate.

So far, we have decided to help support their solution by automating the data load into the worksheets, but we still would like to see a more centralized, integrated solution where the buyers don’t have to do so much manual work to issue discrete POs based on forecasts.

Long story short… has anyone had success using Epicor’s forecasting functionality with multi-level BOMs? What are you doing to purchase to forecasts?

Thanks in advance for the time you took to read this and any suggestions or comments that follow.

Have a lovely day!

-Utah