Hey all, could use your input! I am just starting to play with scheduling in our system, and I am wondering how some of you handle it. Here is our situation:

We are a job shop: Low volume, High mix. I am not looking to schedule months in advance, but for 1 week at a time. On a given operation, we could have 1 operator work on it one day, another the next, and so on. Our schedule changes daily. I can figure out how to do a basic schedule for 1 week at a time, but here are some of the questions I have:

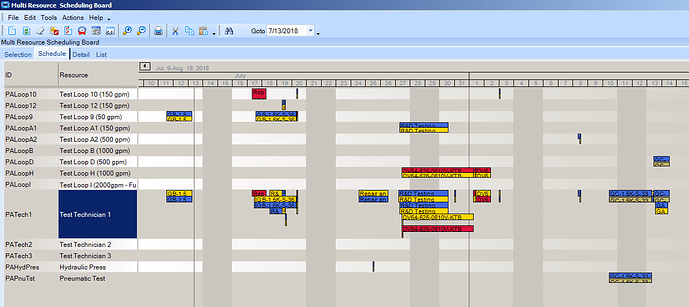

(1) Is there a good way to see a schedule of the machines, and the operator assigned to them for a time period?

(2) When I schedule an operation to an operator, it schedules the full length of the operation. Can I partition it out to say that he is only going to produce x amount of pieces, or schedule him for a certain portion of time?

(3) Do any of you print reports to hand to supervisors to show them expected work for operators in their department? I know there is the work Queue, but I also am looking for a printed report to the supervisor.

Thanks in advance for all the help!