From the online help.

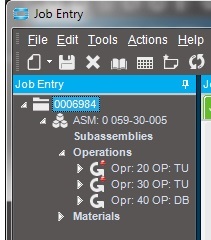

Job Entry - Job Tree View

Navigate to this sheet/program:

- Job Entry > Job Tree View

The Job Tree View visually displays the job’s method of manufacturing

through a tree structure. Each method item is displayed with an icon and

some descriptive text. Use the interface to quickly view the job’s method,

tracking the job’s progress as its quantities are manufactured.

Use the Engineering sheets to click and drag method of manufacturing

items onto the Job Tree View. You can also define what items are displayed

on the Job Tree View; you select these options from the View sub-menu

found under the Actions menu.

Each Job Tree View icon identifies the manufacturing item and in some

cases, indicates the item’s current status. Read the Icon Details section

for a key of each icon and what it means.

Icon Detail

Icon Description

Indicates that this item is a project.

Indicates that this item is a standard job.

Indicates that this is an assembly linked to the job.

Indicates that the assembly is on the critical path. Any delay to an item

on the critical path will delay the job’s completion.

Indicates that this assembly has a problem with the availability of its

material needs.

Indicates an operation that has not been run yet. This icon may also be

coupled with the “tag with a red dot” icon to indicate that there are

material constraints for the operation.

Indicates that this operation is complete.

Indicates that this operation has a problem with its capacity. This icon

may also be coupled with the “tag with a red dot” icon to indicate that

there are material constraints as well as capacity constraints.

Indicates that this is a subcontract operation. This icon may also display

with a red dot to indicate that the subcontract operation has a capacity

constraint.

Indicates that this subcontract operation is complete.

Indicates that this item is a material. This is the default icon for

material.

This icon can appear for one of several reasons:

- This icon can appear for one of several reasons:

These materials have been issued to the job.

- The job material does not have a required date. This is either because

the job was not scheduled, or the material was added after the job was

scheduled.

- The job material is from stock, and it is Make Direct.

- The job material is from stock, and is coming from a different site,

from which the material has already been shipped.

- The job material PO release (if purchased) has a received quantity, or

will be here before the Material Required Date.

Indicates that the backflush location does not have enough on-hand quantity

to satisfy the requirement, but the job material record’s warehouse - plus

the backflush warehouse - does have enough on-hand quantity.

This icon can appear for one of several reasons:

- Not enough stock is available to satisfy this material’s requirement.

- The Job Material is now overdue.

- The job material is from stock, and is coming from a different site,

from which the material cannot arrive by the Job Material Required Date

- The job materials PO release (if purchased) does not have a received

quantity, or will not be here before the Material Required Date.

- The job material is backflushed, but the backflush location did not

have enough on-hand quantity to cover the requirement, and neither does the

job material’s warehouse plus the backflush warehouse.

- The job Start Date is in the past. In this case, there may be enough

material quantity available, but because the Start Date is in the past, the

material is considered late.

Indicates a material with a zero quantity per parent for which nothing has

been issued. The icon will display even after the job is completed and

closed, so long as the material is not issued.

Indicates a material with a zero quantity per parent for which material has

been issued on this job. The icon will display even after the job is

completed and closed.

Indicates that the part revision has changed.

Note: You can configure purchased materials associated with enterprise

configurator parts when they are added as material content in

Opportunity/Quote Entry and in Job Entry.

- These are items for which the Type field has been set to Purchased

in the Part Maintenance > Part > Detail sheet, for which the Enterprise

Configurator check box has been selected in the Configurator

Designer > Status sheet.

- To do this for a job, you add the part to the Material node in

the Job Entry Tree View. After you have added the part, simply

right-click

it, then select Configure to access a Configurator Q&A session.

Thanks,

Norman Hutchins

System Administrator

Howell Laboratories, Inc.