I got this explanation of what a dual UOM class is:

The ‘Dual’ feature was introduced with the ’10.2.600’ release and complements the ‘Advanced Unit of Measure (AUOM)’ functionality. However, you can be use it without it as well, if required. I won’t go into the ‘AUOM’ concept because it is complex. Nevertheless, if you are interested in ‘AUOM’ I can point you to the knowledge resources we currently have or answer any questions you may have.

The main purpose of using ‘Dual UOM’ – without ‘AUOM’ – is to be able to make an update to existing parts that already hold some transactions. Let’s say there are already some part transactions in the system but you need to delete the ‘UOM Class’ the part holds. Since you cannot do this, you can link the existing part with the ‘Dual UOM Class’ and make the two classes communicate, if there are some updates you want but cannot make, because the part is being transacted. Below is some info on the ‘Dual UOM Class’ but you would want to use it most likely with ‘AUOM’. The reason for this is that you don’t need it and can do it with a standard ‘UOM Class’ (Other Class Type). You can define your conversions there and have one class assigned to your part instead of two.

1/ You set a ‘UOM Class’ record to ‘Dual’ in the ‘UOM Class Maintenance’ app by selecting the ‘Dual’ type. You need to have the ‘AMM’ license.

2/ The ‘Dual’ unit of measure class works in conjunction with the ‘Inventory’ base unit of measure class to convert defined units of measure.

IMPORTANT: The base unit of measure for your ‘Inventory’ class must match the base unit of measure you set up in the ‘Dual’ class. This will allow the two class records to link and cross convert with the units

of measure. However, the primary ‘Sales’ and ‘Purchase’ units of measure can be from either the ‘Standard’ or ‘Dual’ unit of measure classes.

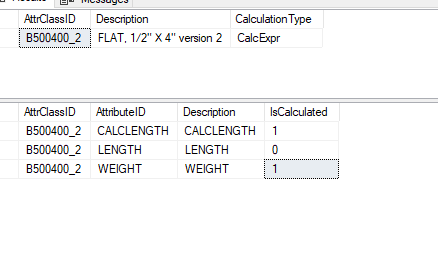

For example, you create a new part record. Let’s call it ‘RL’. When you create a part, you select the ‘UOM Class’ called ‘Pound’. Let’s make it the weight-related class. You select the ‘UOM Class’ in the ‘Part’ app here. This is a standard ‘UOM’ class with the ‘Other’ class type.

3/ The selected ‘Pound’ UOM class includes ‘2’ UOMs – ‘SH’ (Sheet) and ‘LB’ (Pound). The ‘LB’ UOM is set to ‘Base UOM’. You do this in the ‘UOM Class Maintenance’ app.

4/ As a result of you selecting the ‘Pounds’ UOM Class in the ‘Part’ app when you were creating your part record, the ‘Inventory’ UOM defaults to ‘LB’. This is because you selected ‘LB’ as your base ‘UOM’ in the ‘UOM Class Maintenance’ app.

5/ Next, create another ‘UOM’ class but this time select ‘Dual’ as the ‘Class Type’.

6/ The ‘Dual’ class holds ‘LB’ as the ‘Base UOM’. For your ‘SH’ unit of measure, you specify a Conversion factor. Let’s say you want ‘1’ SH to weight ‘511.2’ LB.

Therefore:

Assume, your warehouse holds ‘5,122’ pounds of steel that consist of ‘10’ sheets (warehouse bin).

Now, the system would only list the ‘Dual’ UOM Class records that hold the ‘Dual’ class type (UOM Class Maintenance) and that include the same ‘Base UOM’. A standard UOM Class needs to hold ‘Base UOM’ that is also ‘Base UOM’ for the ‘Dual’ class. I am talking about the list of classes that you can select in the ‘Part’ app.

In summary, the ‘Dual’ class allows the two class records to link and cross convert with the units of measure. This is ‘Advanced Unit of Measure’ related but can work independently as well. That is why you can select it in the ‘Part’ app on the ‘Attributes’ card.