Our BOM contains a mix part that is pull as assembly, and many of our BOMs use other parts in them that are also pull as assembly. See example below

Recently we have adjusted the BOM of our mix, removed 1 part from the BOM and replaced with another (with a new qty/parent).

We currently have over 500 jobs that are already created and scheduled. All these jobs will need to have the job materials deleted and re-get details so that it pulls in the new BOM from the mix part number.

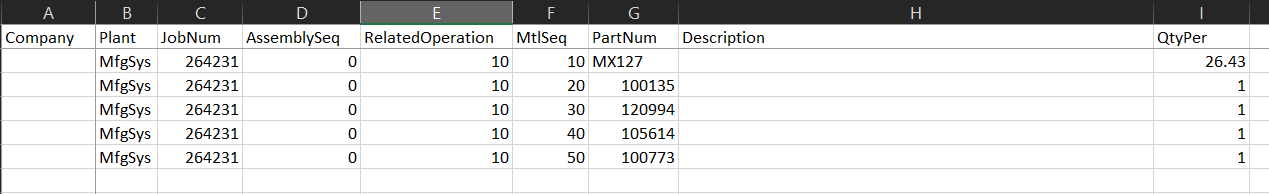

I can delete all job materials easily through DMT. What I am struggling with is how to DMT the job materials back in. How do you arrange a DMT when it includes pull as assembly items?

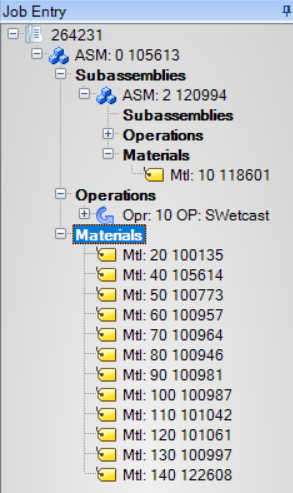

This is what the job layout looks when you get details through Epicor.

It expands the BOM of the mix into the job and creates a subassembly for the other part that is pull as assembly.

If I add materials through DMT as below. First of all I actually have to reverse the order of the MtlSeq in the DMT to be from highest to lowest. Otherwise it’ll expand the mix BOM details (MtlSeq 10) into MtlSeq 20 through 100 and then it’ll overwrite those materials with the rest of the BOM details from the DMT that use the same MtlSeq.

Running it in reverse MtlSeq inputs the other materials first, then expands the mix BOM to the next available MtlSeq.

This DMT does not create a sub assembly for part 120994 and instead just adds it as a material. Adding a 2 to the AssemblySeq for that part kicks a bunch of errors in DMT as well and does not create a sub assembly.

What’s my best method for DMT in this situation? Re-getting details on 500+ jobs should be more tedious than figuring this out with DMT.