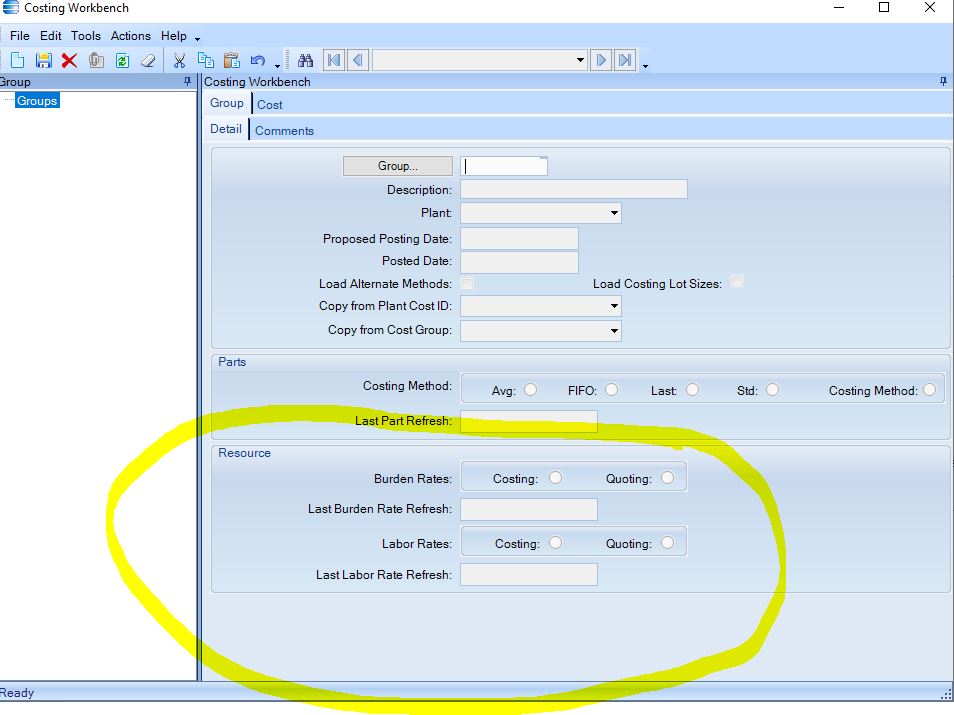

I need help understanding the different options within the costing work bench when I do a roll up.

In the costing workbench there is an option to select either “Quoting” or “Costing” in the resource group section (See attached). When Quoting is selected all parts seem to roll up as expected and match the BOM. When Costing is selected, some parts roll up as expected, some don’t (labour rates are the same for costing & quoting). As far as I can see the parts which don’t roll up correctly are just showing the top level costs.

I have spent time looking at the difference in how 2 parts were set up and noticed that the “Non-stock item” box was ticked on one part and not on another. The one which rolled up correctly for both costing & quoting had non-stock item ticked. The one which rolled up correctly only when quoting was used and only pulled top level assembly costs when costing was used, didn’t have the non-stock item ticked.

Some further digging showed that when the non-stock indicator was ticked the part automatically defaults to “Pull as assembly” and “View as assembly”.

Now the questions:

What is the difference between “Costing” & “Quoting” methods of roll up?

How do “Pull as assembly” & “View as assembly” affect part costs during roll up?