We are looking for a way to use configurator to create a job for a configured component. We are using Epicor 9 05 702 A

We are using a mix of place holders in the BOM and actual parts and each are controlled with the “Keep When” rules. If we add a part of a place holder in as a sub assembly on the job and put “Keep When” rules on the BOM of the sub assembly the correct parts are kept, however we need to create a job for that place holder part.

If we change the place holder to a material we are able to create the job for that part in the BOM, but we cannot put rules on the BOM of a material.

Is there a way to create a job for something on a BOM in a configured part and control that BOM with rules?

Do you need to have a job for the sub-assembly (like for time tracking, or scheduling)?

If not, just attach all the sub-assembly’s materials to a different operation.

Or is the fear that as the definition of the sub-assembly changes, it will get missed if the configurator isn’t updated?

FWIW - I used to make the base BOM of configured parts with just a single part as place holder. Then update the quote and job detail’s PartNum, QtyPer, based on the configurator inputs. This became a nightmare to maintain.

I now make a Super-BOM - one that contains every part that any configuration may use - and then do the “Keep When” rules to exclude the parts not needed. But I still have to set qty’s based on inputs.

Yes, we have to have a job for the part that is currently a sub assembly because it is put together in a different area. When we make the part a material we get the job, but the we cannot put rules on the BOM to keep the correct parts.

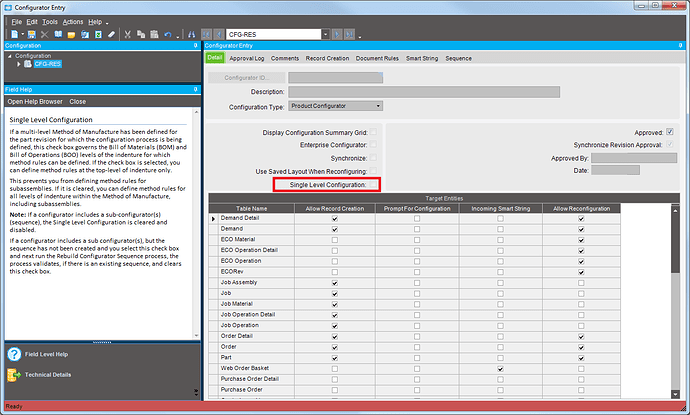

Do you have the Single Level Configuration checked in the Configurator Entry? I think having that un-checked (Allowing multiple level configurations) as well as the Pull as Assembly Flag checked on the material would give you what are you are looking for but also allow you to modify the materials in the subassembly.

Just to clarify things…

Does the sub-assembly change based on the inputs of the top level part?

I believe E10 allows you to make P/N driven configurators. Not sure if E9 has this as well.

Your sub-assembly would be a P/N driven configuration - with its own keep when rules based on its P/N. Your top level part would dynamically build the P/N of the sub-assembly needed. This diverges from the Super-BOM with every concieveable material included.

Yes, we already have the Single Level Configuration box unchecked. We are able to set rules on the materials under the sub assembly, but we aren’t able to create a job for that sub assembly.

If we put the part in as a material we can’t control the BOM under it, but then we can create a job for the part.

Yes, the BOM for the sub assembly changes bases on the options picked in the configurator.

I was kind of afraid that the answer may be that this will be much easier in E10. We currently are using a hybrid BOM. We have most parts listed on the BOM, but in some cases we do put a place holder in and replace it with the correct part from the inputs of the configurator.

Where our biggest issue comes is we need to create a job for one of the parts listed on the BOM and we can’t get that to work with a dynamic BOM.

When you manually make a multi-level MOM in Quote entry, it makes entries in the QuoteAsm table for sub-assemblies.

The sub-assemblies for a given MOM are given sequential numbers in the AssemblySeq field.

Maybe you need to make placeholder for the Assy in the BOM used for the configurator.

The placeholder assy in the main BOM would then have its own components/placeholders. Then the configurator code would tweak the sub-assembly’s components P/N’s, qty’s etc…

Hey Calvin,

Thank you so much for your time on this!

Yes, we do have a placeholder in the BOM. The placeholder is a subassembly and we are able to set rules on the materials and assemblies under that place holder. However, when we create the job for the top level config we are not asked to create a job for that part that took the place of the place holder. The part for the place holder just shows up on the job for the top level config. I need a separate job for that part that took the place of the place holder.

Isn’t needing a separate job what you wanted in the first place?

We don’t use sub-assemblies (other than ones we make and stock) on jobs, so my understanding isn’t from experience. But if you made a regular (meaning non-configurator) multi-level MOM in a quote, which was then converted to an order, does the Job Manager inform you that another job (for sub-assy) is required? Does it make it for you automatically? Or do you have to enter the Sub-assy’s P/N into the Job Manager to see the demand for it?

Review the fields in

Epicor - Plan As Assembly

and

Auto-Consume stock

Plan As Assembly - should really be called PLAN TO ASSEMBLE, because if checked, EPICOR will presume you want the components to be issued to the job of the upper-level to build the sub-asm as part of the upper-level job.

While these things are being generated as requirements per configurator, you do not specify IF the sub-assm is standard or configured.

If it is not a standard sub-asm, then you would not stock em! (but you might consider stocking common componenets to speed-up providing the sub-asm to the upper-level requirement. .

Yes, we are looking to get a second, separate job.

If we create a non-configured quote and push it to an order, the sub-assembly does not show up for us to create a job that way either. Normally the jobs that need to be created show up on the planning workbench and we release them from there.

We use service connect to create those parts with sub-assemblies. I collect all the information needed in the configurator section and then use some sort of trigger that passes the information needed by service connect.

Brenda J. Mohr

Humtown Products

Joe,

Thank you very much for your response! What you are explaining seem to me to sound like what we want to do. One question, though, is the Plan as Assembly only available if you are running MRP? We currently do not use MRP.

OK in ur not using MRP, but (IMO) it helps in scheduling… and then running PO Suggs, as well, provides more input.

MRP and PO suggs are, SUGGESTIONS.

Being able to have an ERP application look beyond the top level requires settings suggested.

PLAN as Assembly is just a chk-box that MRP utilizes, along with Auto-consume stock, to figger-out what jobs are needed to provide sub-assm availability and end-product synergy.