Hi Guys,

Who has a BPM that’s working that prevents one from overshipping.

Pre-Processing Method Directive on CustShip.Update with a custom code node which uses the following:

var ShipDtl = ttShipDtl.Where(sd => (sd.Added()) && ((sd.OurJobShipQty + sd.OurInventoryShipQty) > (sd.SellingReqQty - sd.SellingShippedQty))).FirstOrDefault();

if(ShipDtl != null)

{

var message = "You are attempting to overship this line, please correct before you can continue.";

throw new Ice.Common.BusinessObjectException(new Ice.Common.BusinessObjectMessage(message){Type =Ice.Common.BusinessObjectMessageType.Error,});

}

Thanks SueLowden

I have noted when it throws that error then you put the correct remaining quantity one can save and the error disappears.

After this if you change the ourshipmentquantity to a higher value than the remaining quantity it allows one to oveship.

Thanks Jane

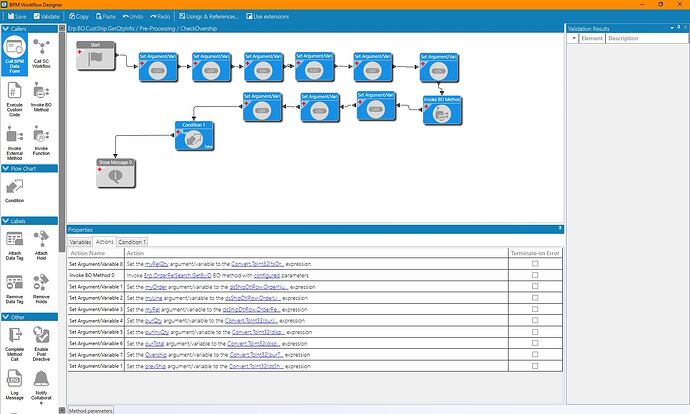

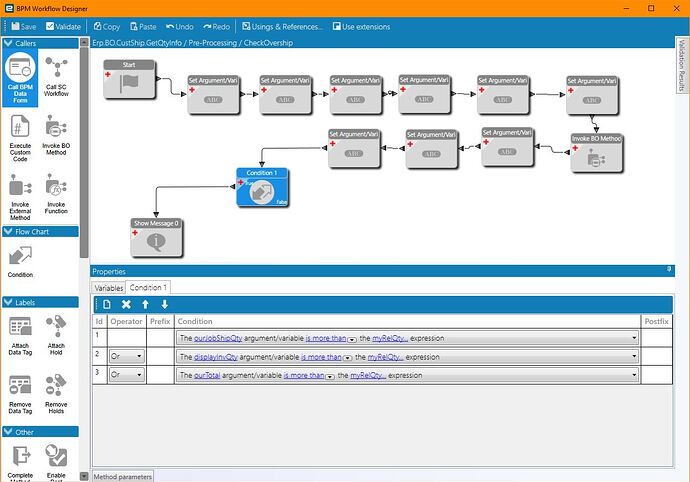

We use a Method Direvtive on Erp.BO.CustShip.GetQtyInfo > Pre-processing.

Hey! Pay Attention!

You are about to overship this order by <Overship/> pieces!

The release is requesting <myRelQty/> pieces.

<prevShip/> pieces have been shipped already.

You entered <ourQty/> from job, and <ourInvQty/> from inventory.

If you are sure this is correct, please continue. Otherwise, reduce the shipment amount.

The setup:

This doesn’t stop them from over-shipping, but it does warn them and give enough information to make a choice about how to continue.

Just add “sd.Updated()” to the linq statement to fix that.

var ShipDtl = ttShipDtl.Where(sd => ( sd.Added() || sd.Updated() ) && ((sd.OurJobShipQty + sd.OurInventoryShipQty) > (sd.SellingReqQty - sd.SellingShippedQty))).FirstOrDefault();

if(ShipDtl != null)

{

var message = "You are attempting to overship this line, please correct before you can continue.";

throw new Ice.Common.BusinessObjectException(new Ice.Common.BusinessObjectMessage(message){Type =Ice.Common.BusinessObjectMessageType.Error,});

}

Great my issue now sorted.

I know that you have this “solved”, but there is another scenario that you need to check for:

- create one order, one detail, one release for 100 pieces

- create TWO packslips, each for 75 pieces… since neither of them exceed the order quantity they are both ok

- ship both of them, and you are exceeding the qty.

Make sure that your BPM catches this condition as well.

I found for one customer that we had to not only verify THIS packslip, but all other open packslips as well in order to catch this type of condition.

I didn’t even think of that, we generally have 1 release per order. I’ll see if I can come up with a bpm to monitor those multiple release situations as well.