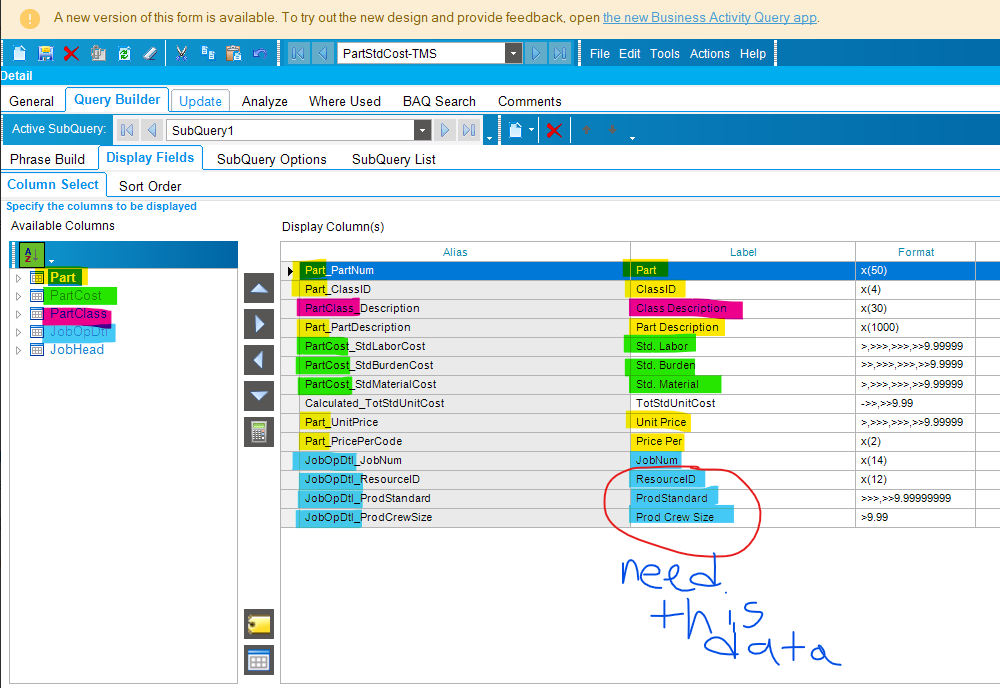

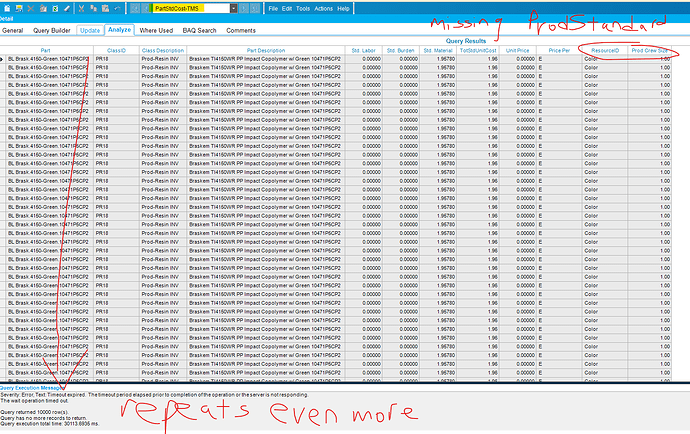

The problem is (I think) you’re WANTING one result (row) per part… and want those results to include Resource ID, ProdStandard, and ProdCrewSize.

The problem is those (3) fields are included for each operation on the METHOD to make each part. Each operation has its own scheduled ResourceID, each has its own ProdStandard, each has its own ProdCrewSize.

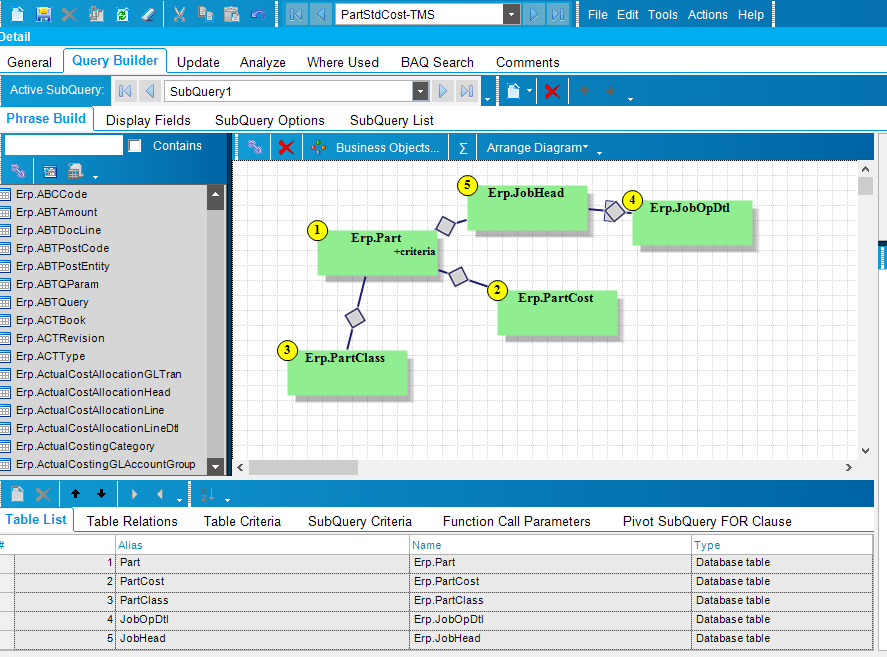

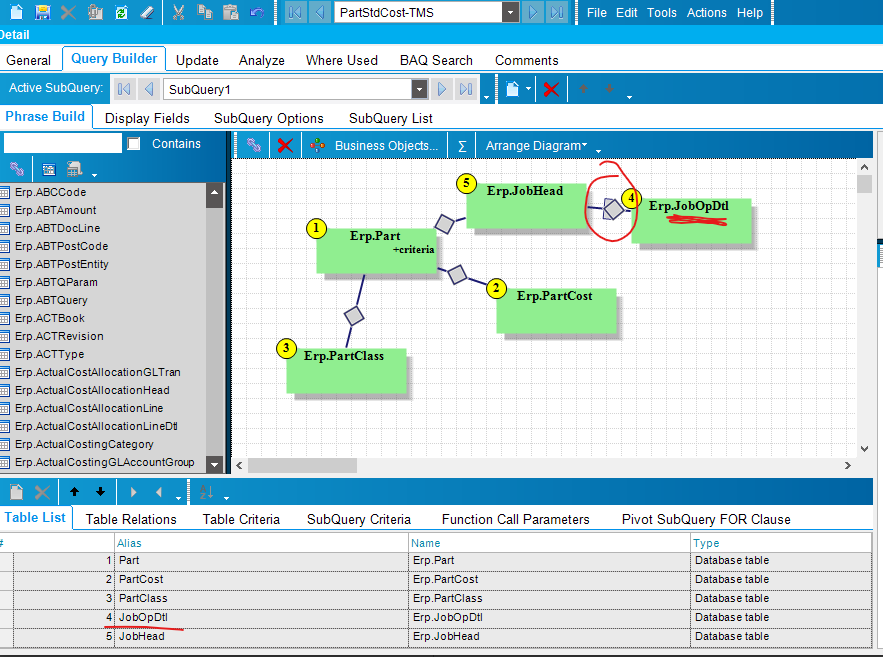

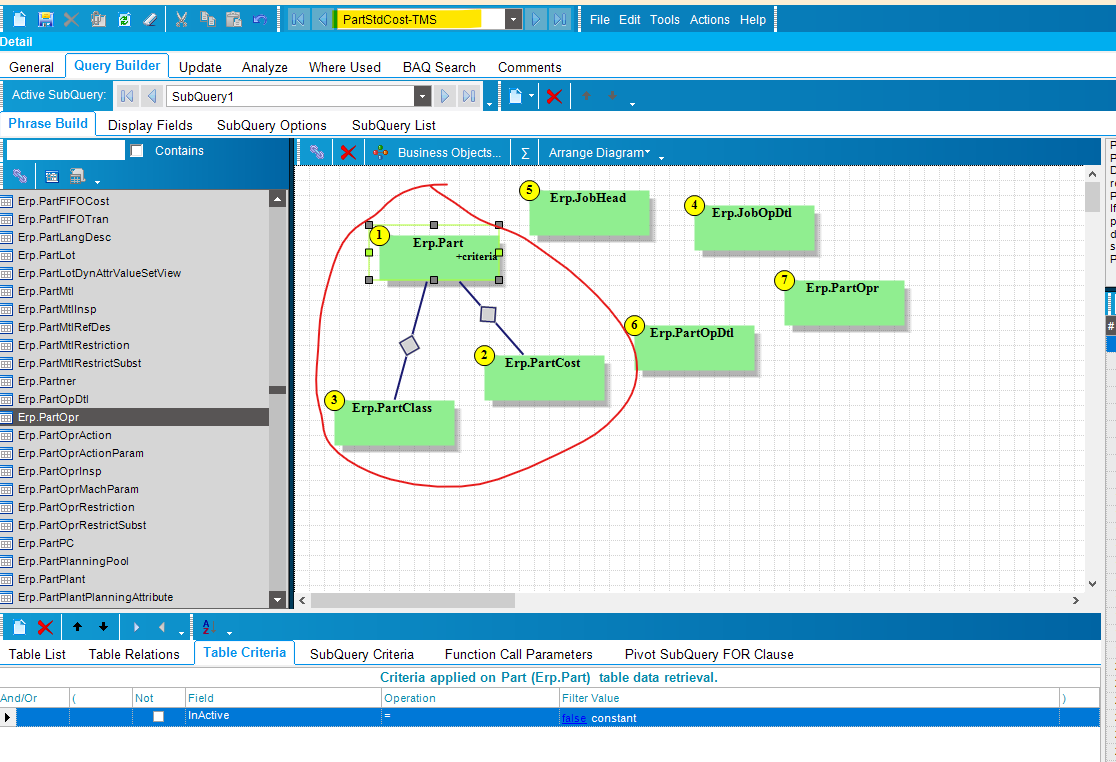

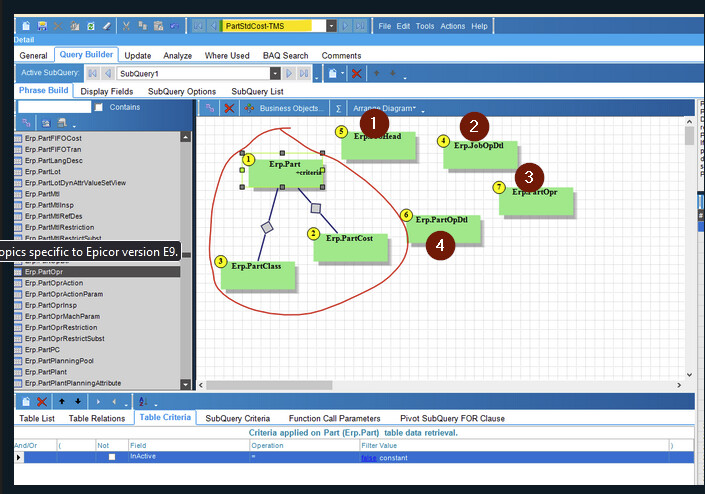

This is what @josecgomez was getting to early on. Just looking at PARTS, is a one-row per part query. But as soon as you add tables like JobHead, or JobOprDtl, or PartOpr… its now a one-to-many query. Each PART could have multiple job records (resulting in more rows), each PART could have more than one operation in its method (resulting in more rows), etc.

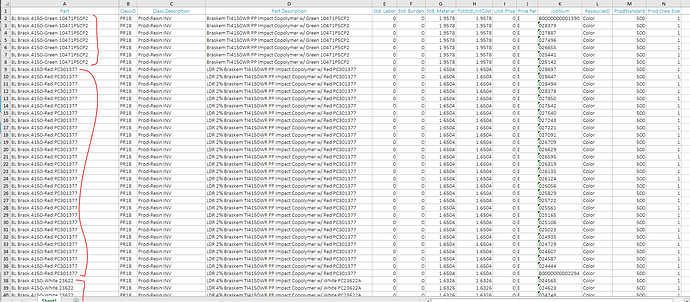

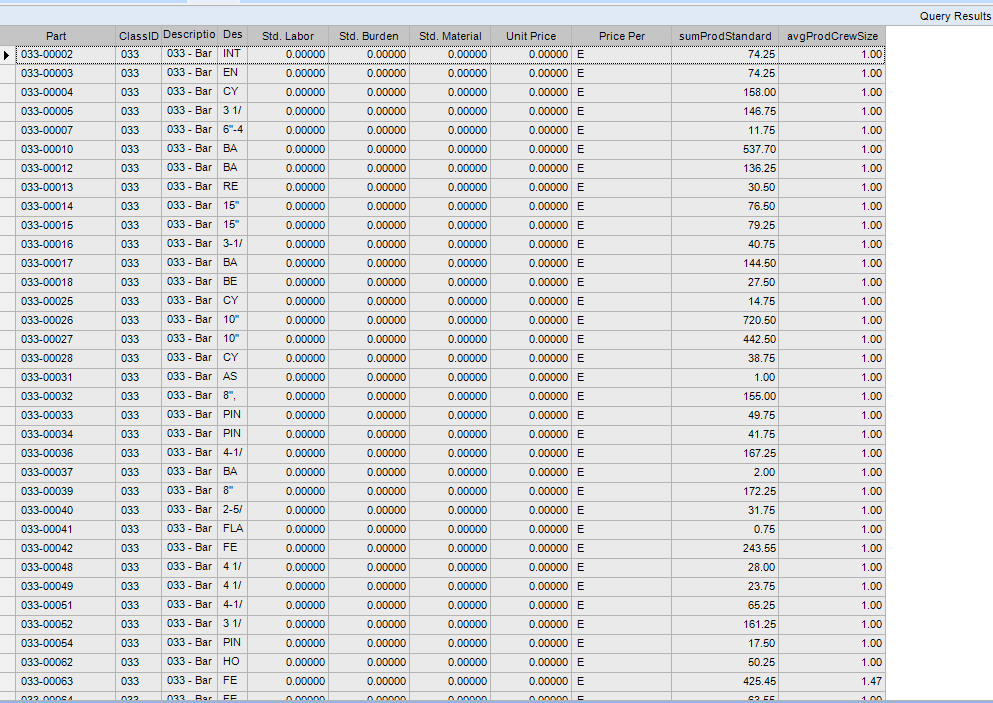

So, for example, if you have (10) operations to make part XYZ… you’re going to end up with (10) rows of results… one for each operation.

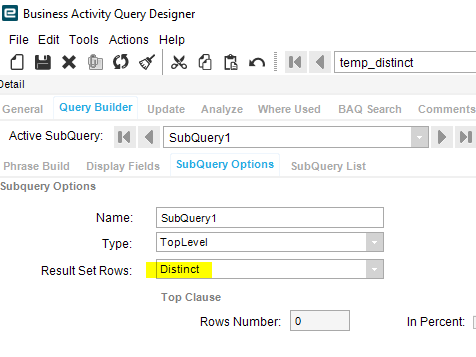

I’M MAKING AN ASSUMPTION… that you might be looking for the TOTAL (sum) of the ProdStandard??? How many total hours to make each part??? In that case, you could sum the ProdStandard values.

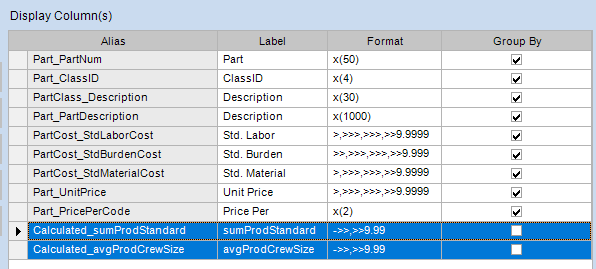

You could also “average” the ProdCrewSize to get… relatively close to a true answer. it would average the crew size for each operation and give you that overall average, per part.

I’m not sure how you would get an aggregate of the ResourceID… I guess if you really need it, maybe you could concatenate a string of those results???

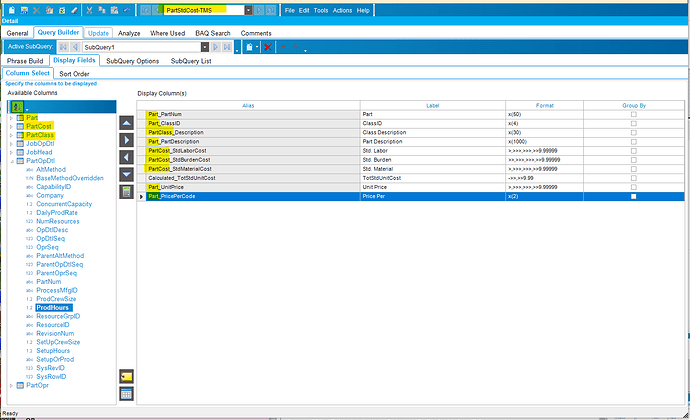

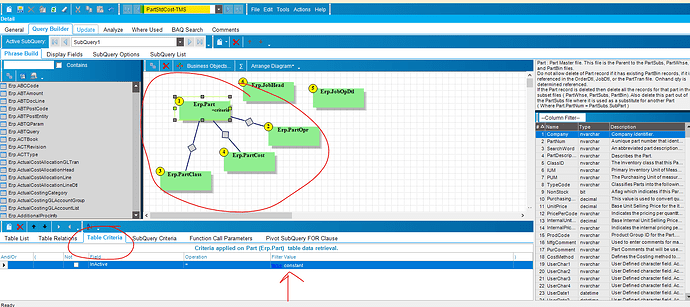

But I was able to recreate and get some aggregate values of ProdStandard & ProdCrewSize… again, going off of my ASSUMPTIONS above.

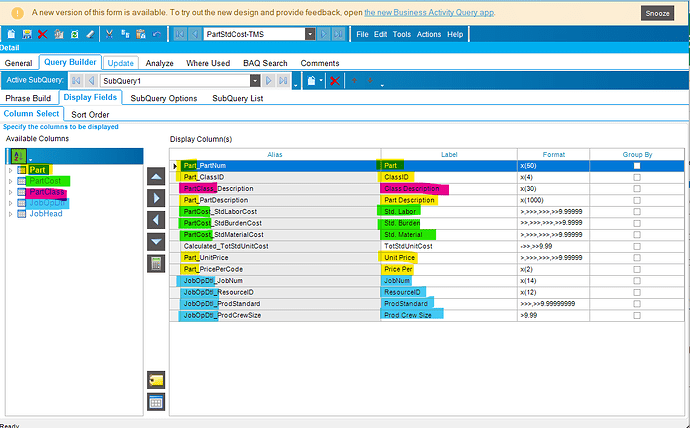

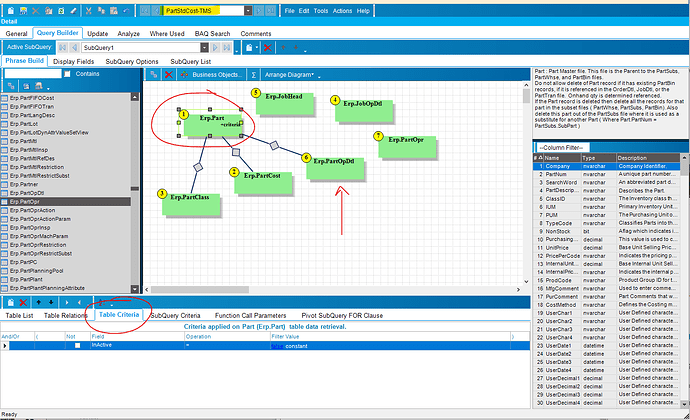

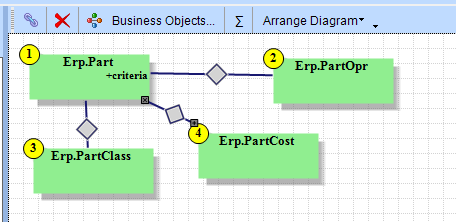

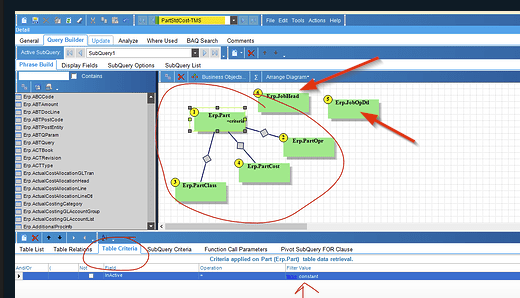

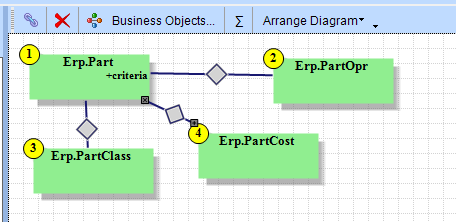

I used the PartOpr table to get ProdStandard & ProdCrewSize values:

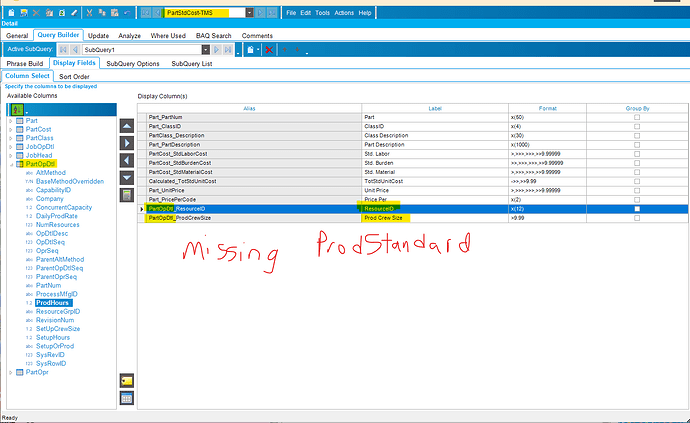

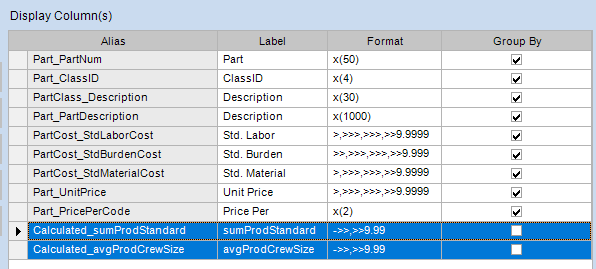

I created (2) calculated fields to combine the ProdStandard & ProdCrewSize values:

Query Results: (NOTE… my company doesn’t use Std. Costs, nor add Unit Price values on our parts… so that’s why I’m not getting any results there). But I did get (1) Row per part number: