Hmmm… I have never tried price breaks & component level pricing… I have actually not done too much with component pricing, as it is not as common in use.

@ScottLepley - Any reason why you can’t use price breaks on the Sales Kit itself, without enabling component pricing?

Well, I’m sure we can, but Sales would like to do otherwise!

The kits all have 2 standard parts, Part 1 and Part 2, and one variable part, from Part A through Part Z. The kits are set up to use component level pricing. Sales would like to set up quantity price breaks at 10 pieces for both Part A and Part B, so that if a customer would buy 3 of kit 12-A, 3 of kit 12-B, and 4 of kit 12-C, the quantity break pricing for Part A and Part B would be triggered.

I’m not seeing any way to accomplish this with standard Epicor, hence my post.

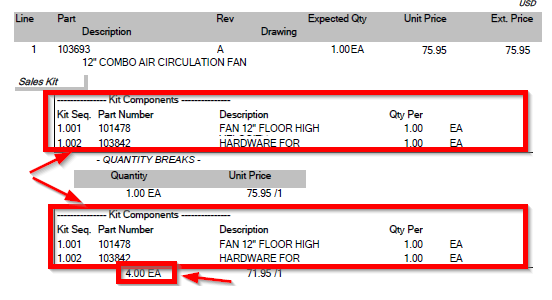

Be careful - The Print Quote Form will duplicate the kit complonent lines for each price break. Customers don’t like it, since they think it’s multiple lines when they are only buying one.

Epicor says it’s “Working as designed”:

In case you use Kit component with quantity breaks, for every quantity break the form will print the lines and the Quantity breaks, the quantity breaks is per line.

Feel free to reference Case CS0001382376. Screen shot is a kit part we have with a quantity break on 4 units…

@askulte - in your screenshot, do price breaks exist for A) just the kit P/N, B) just the components, or C) Both?

And is the Kit setup up to use component pricing?

Because I did a test, and price breaks on the components don’t seem to roll up to the sales kit.

Calvin - Sorry, we use parent pricing, not component pricing on our sales kits. The breaks exist for the parent price.

Scott, We have the same issue. We have different discount levels for each component in our sales kit. I have tried to use component pricing in many different ways, but was unsuccessful. Seems like it should be straightforward, but it isn’t. We end up using Parent Level Pricing, but that does not allow you to make component substitutions within an order easily without having to recalculate everything. It also makes any sales analysis report of the kit components useless, as it will bring in the base price of the components instead of the discounted amounts. Very frustrating.

@timshuwy

I am working with an #e9 customer and they are experiencing a lot of odd issues with Kits and I am slowing correcting most of their problems, but I have come down to this Plant/Site setting for Non-Stock & Qty Bearing. About half their kits are Non-Stock and half are not and no one has a reason for the difference. I am trying to ‘normalize’ all the settings to easy troubleshooting.

This post has been very helpful. I worked with Sales Kits all the time and honestly I’ve never did anything with the Non-Stock setting, but with all their odd issues and seeing this inconstant setup I’m starting to wonder. I reviewed the Sales Kit Course and it’s not very clear either.

So I’m not sure I understand when you say ‘leave Non-Stock’ …as in enable Non-Stock?

Also what about the Quantity Bearing setting, I would expect that should just be left disabled.

So you you mean for Sales Kits that Non-Stock should be enabled or disabled? Also, shouldn’t Epicor manage this setting itself then or is there a reason for the option?

Thanks!

I know this is super late, but…

We have all of our Sales Kits set to:

Qty Bearing = TRUE

Non Stock = FALSE

There is another issue I found with Sales Kits.

If you edit the part number of a Sales Kit on the order line, sometimes it updates the kit components and sometimes it doesn’t.

PRB0226683

I am running 10.2.500.9

They claim this is fixed in the newer version. I will believe it when I see it. (Hopefully sometime next week)

So if you are seeing “odd issues” with Sales Kits, you might want to check this out.

A couple of notes on your video…

Did you ever check the “Kit Detail” tab on the Lines sheet? Maybe that updated but the Tree view on the left pane wasn’t showing properly (but I doubt it).

An interesting test would be to make a quick BAQ of just the OrderDtl table, for just that order number. Then refresh the BAQ after each change (and save) in Order Entry.

Or run a trace and see what what data the BO methods are using.

And another thing to consider, is that a line for a Sales Kit also creates an order line for each component. When you created the first line for P/N 1955, it created 6 Order Lines (1 for the 1955 P/N, and 2-6 for the kit items). Your “second” line of the order was really line 7.

I know your example changed line 1 to a SK with fewer items, but what if it had had more than P/N 1955 did? Would those extra SK items overwrite existing order lines? Get tacked on the end (SK on Line 1, first 5 components on lines 2-6, and the remaining after the last order line)? Or just lose those extra components all together?