I think the “Job Adjustment” @Banderson is talking about, is real through Job Entry.

Nope. There is no where in job entry to adjust that checkbox.

edit I stand corrected. It’s not in there.

So I’m wondering if I am thinking about this wrong. Here, when the need to make the replacements, they (the shop floor) just do it. (usually it’s steel or something) so the transaction happens to relieve inventory, then a suggestion shows up for what it was robbed from. Maybe that’s what you were seeing? If you were to complete the rest of the requirements, it will change inventory, and your suggestion will increase. But that doesn’t fix the problem if you don’t have enough.

I think that Epicor doesn’t decide if you want to replace scrapped parts or not. Some places make 500 on a job and if the yield was only 480 and 20 scrapped, the job just gets closed with those numbers. For others (like my company) we need the bad parts still made, but Epicor doesn’t react to that. (I wish it did though).

My next thought is, instead of scrapping the assembly, can you try scrapping the material instead? (or on top of?)

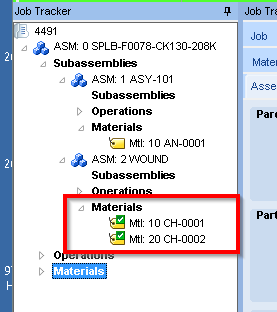

@swilliasc111 - What is shown in the Job Tracker tree? Is the ASY checked as complete? Or just the Materials?

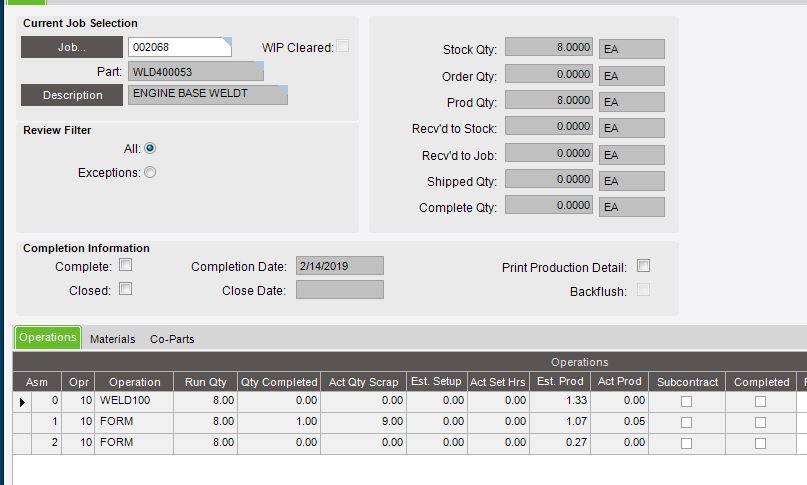

In the example below, I entered Prod and Scrap Qty’s (using Time and Expense) For ASY 2, such that the total produced (Prod Qty + Scrap Qty) exceeded the Total Required for the job. And now it shows the Materials as complete, but not the ASY.

Run the Job Pick List to see if it still includes the components for the ASY…

The materials did not show on job pick list.

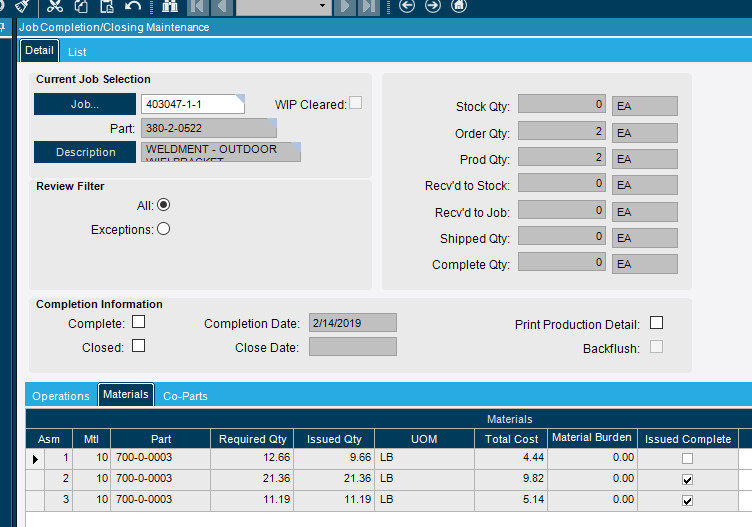

The materials are checked complete, but the operation does not show complete.

did you try scrapping the materials? Does it subtract from what was issued?

Where do you scrap materials, currently we are scraping operations that issues materials as we all talked about.

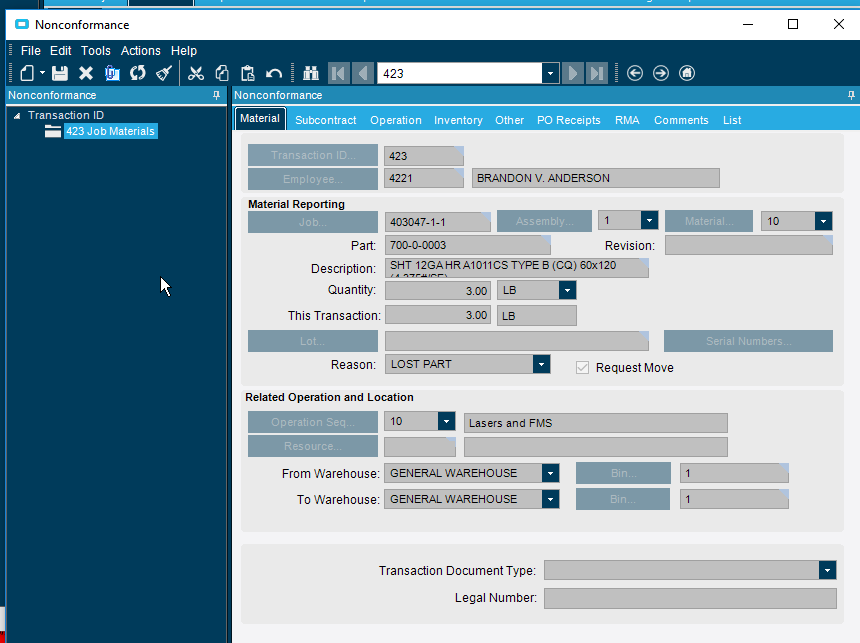

do you have the QA module? You would start a non-conformance and run that through it’s process.

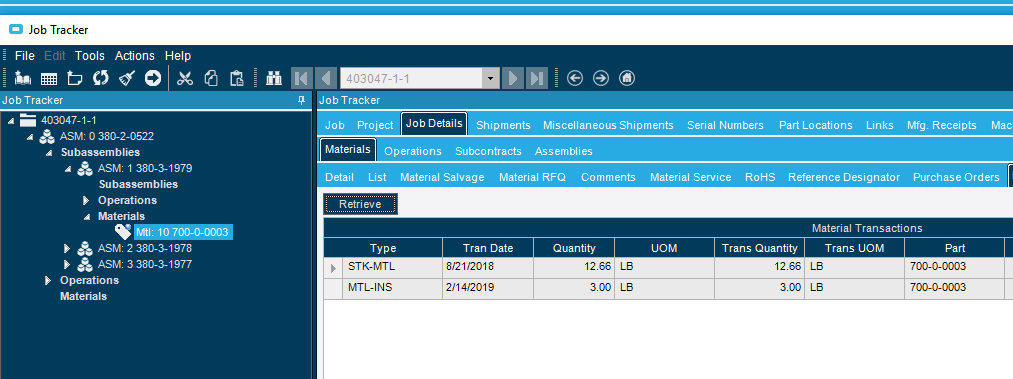

So I just started a non-conformance for this part. The required quantity was already issued, and the checkmark was green. Then I made the non-con, a transaction showed up for MTL-INS. Now the job shows the blue dot, which means it will require more.

I tried this method it does work as you showed.

I was trying the non-conformance on the end activity to see what this would provide and the result of a non-conference entry was the operation did not show completed quantities, but the parts will be issued.

Have you used non-conference against operations in a way that MRP would be leveraged?

We don’t use MRP, so I’m not sure on that. But I think it comes back to the idea that some companies don’t need to re-make scrapped parts, so Epicor doesn’t automatically handle it. It would be nice if they had two modes so that each business model could have something that works for them, but I can still see a problem with so many gotchas that it would be really hard to implement a solution good enough to be available for general release.

You probably could get something customized to automate some of this stuff, but it wouldn’t be a trivial customization.

I appreciate the help! A customization would probably create a non-conformance against the materials under an operation that has a non-conformance entry.

exactly. It could also adjust quantities on the job instead if you wanted it to. Depends on how you want to see the data.